Baltic Birch Plywood. You've probably heard the name whispered with a certain reverence in woodworking circles, or seen it specified for high-end cabinetry and demanding construction projects. But what exactly is this famed plywood, and why does it command such respect? As Allen, representing a factory in China that has been producing engineered wood products like LVL Timber and various types of plywood for years, I've seen firsthand the difference quality materials make. This article is your deep dive into the world of Baltic Birch Plywood. We'll explore its unique characteristics, unravel the mysteries of its grading system, discuss common sizes and full sheets, and highlight why it's a superior choice for everything from intricate furniture and precise jigs to robust cabinet construction. Whether you're a seasoned professional like Mark Thompson, a procurement officer looking for reliable B2B suppliers, or a hobbyist aiming for top-tier results in your shop, understanding Baltic Birch Plywood is key. This guide will equip you with the knowledge to select the right grade and sheet for your project, ensuring you get the performance and aesthetic you expect from this exceptional wood product.

What Makes Baltic Birch Plywood Stand Out from Other Plywood Types?

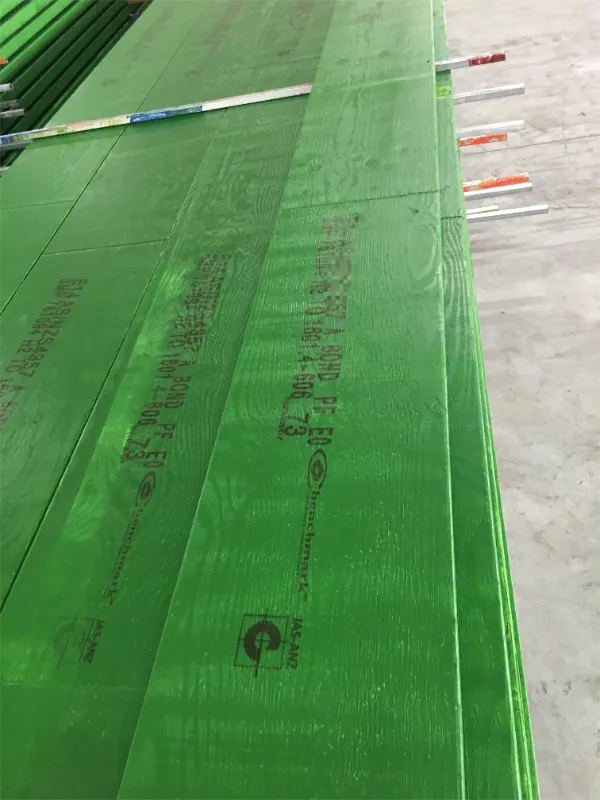

When you first encounter Baltic Birch Plywood, its most striking visual feature is often its edge. Unlike many other plywood products that might have fewer, thicker layers, or visible voids, Baltic Birch boasts a multitude of thin, uniform veneer plies. This isn't just for show; it's fundamental to its superior qualities. Originating primarily from the Baltic states (Latvia, Estonia, Lithuania) and Russia, this plywood is typically made from birch veneer throughout its entire thickness. Each ply is consistently thin, often around 1.5mm, and laid up with alternating grain directions, just like any other plywood. However, the sheer number of these plies contributes significantly to its strength and durability, stability, and excellent screw-holding capacity.

The core of Baltic Birch Plywood is another defining characteristic. It's virtually void-free. This means that when you cut into a sheet, you won't find those frustrating empty pockets that can compromise structural integrity or mar a finished edge. This consistency is a result of meticulous manufacturing processes and the use of high-quality birch veneer for the inner plies, not just the face veneer. This void-free core also means the plywood is incredibly stable and resistant to warping and twisting, making it a reliable material for projects demanding precision. At our factory, Jsylvl, while we specialize in a range of products including Structural Plywood for heavy-duty applications, we deeply appreciate the engineering principles that make Baltic Birch such a premium product.

How Do I Decode Baltic Birch Plywood Grades like B/BB and BB/CP?

Understanding the grading system for Baltic Birch Plywood is crucial for selecting the right material for your project and ensuring you get value for your money. The grades typically refer to the quality of the face and back veneer of the plywood sheet. You'll often see grades expressed with two letters, like "B/BB," "BB/BB," or "BB/CP". The first letter denotes the quality of the "front" or "best" face, and the second letter denotes the quality of the back face.

Here's a general breakdown of common Baltic Birch Plywood grades:

- B Grade: This is the highest grade. The face veneer is a whole piece, uniform in color, smooth, and free of defects. You might find occasional tiny pin knots or very light mineral streaks, but overall, it's a clear and consistent surface, perfect for a natural finish.

- BB Grade: This is still a high-quality face. It allows for more color variations, small sound knots (tight knots that are solid), and some mineral streaks. Crucially, BB grade veneer may have small, oval-shaped wood patches (often called "football patches") that are neatly inserted to repair defects. These patches are usually well-matched in color and grain. This grade is excellent for many applications where a mostly clear surface is desired but minor, repaired imperfections are acceptable.

- CP Grade: This grade allows for more unlimited sound knots, repaired splits, and more noticeable color variations and patches than BB. The patches might not be as perfectly matched. While the surface is still sound and smooth, it's less visually uniform. It's a good utility grade for surfaces that won't be as visible or will be painted.

- C Grade: This is a lower utility grade, permitting open knots, splits, and other defects that are not repaired. This side is typically used for applications where appearance is not a concern at all.

So, a sheet graded B/BB would have one face of the highest quality (B) and the other face allowing for some patches and sound knots (BB). A BB/BB sheet would have both sides meeting the BB grade criteria. For many woodworkers building cabinets or furniture, BB/BB is a very popular and cost-effective choice, offering a good balance of quality and price. The inner plies of true Baltic Birch Plywood are generally of a consistent, high quality regardless of the face grade, contributing to its overall stability and void-free core.

What Are the Standard Sizes and "Actual" Thicknesses for a Baltic Birch Plywood Sheet?

One of the somewhat unique aspects of Baltic Birch Plywood, especially for those accustomed to standard North American plywood sizes, is its typical sheet size. The most common size for Baltic Birch Plywood is 5 feet by 5 feet (approximately 1525mm x 1525mm). This square size can be very convenient for many projects, minimizing waste for certain component sizes. While some suppliers might offer it cut down or even in 4'x8' sheets, the 5'x5' full sheets are the traditional offering.

When it comes to thickness, Baltic Birch Plywood is usually sold in metric thicknesses. Common thicknesses include:

- 3mm (approx. 1/8 inch)

- 6mm (approx. 1/4 inch)

- 9mm (approx. 3/8 inch)

- 12mm (approx. 1/2 inch)

- 15mm (approx. 5/8 inch)

- 18mm (approx. 3/4 inch)

- 21mm, 24mm, and even thicker options are available.

It's very important to note the difference between nominal and "actual" thickness. Because it's a metric product, an 18mm sheet is very close to, but not exactly, 3/4 inch. Always measure the actual thickness of your stock before setting up cuts for joinery, especially if you're working with tight tolerances for things like dadoes or grooves. This precision is something we, as manufacturers, pay close attention to, whether it's for our Non-Structural Plywood or more specialized engineered wood products. Consistency in thickness is a hallmark of quality Baltic Birch Plywood.

Why is Baltic Birch Plywood the Go-To Material for High-Quality Cabinets and Furniture?

There's a reason discerning woodworkers and high-end furniture makers often specify Baltic Birch Plywood. Its inherent qualities make it exceptionally well-suited for these applications. Firstly, its strength and durability are outstanding. The multi-ply construction with high-quality birch veneer throughout creates a panel that is incredibly strong and stiff for its thickness and weight. This means cabinet boxes are robust, shelves can bear significant loads without excessive sagging, and furniture pieces are built to last.

Secondly, the stability of Baltic Birch Plywood is a major advantage. It's far less prone to warping, twisting, or cupping compared to solid wood or lower-quality plywood. This dimensional stability is critical for cabinet doors that need to stay flat and for drawers (drawer sides are a classic use for Baltic Birch) that must operate smoothly. Furthermore, its excellent screw-holding capacity, thanks to the dense, void-free core, ensures that hardware stays put and joints remain tight. You can drive screws close to the edge without the plywood splitting, a common issue with softer core materials.

Lastly, the aesthetic appeal of Baltic Birch Plywood cannot be overlooked. Even in a BB grade, the face veneer has a pleasing, fine grain. But it's the edge that truly shines. When left exposed and finished, the layered edge provides a unique, contemporary look that many designers and woodworkers find attractive. There's no need for edge banding if you appreciate this aesthetic. This makes it ideal for modern furniture designs, shop fixtures, and even children's toys where a durable, attractive, and safe edge is desired. The fine texture also takes finish exceptionally well, whether it's a clear coat to highlight the natural wood or a painted finish.

Is Baltic Birch Plywood a Good Choice for Durable Jigs, Fixtures, and Shop Projects?

Absolutely! For anyone serious about woodworking or needing precision in their shop, Baltic Birch Plywood is a top-tier material for creating jigs, fixtures, and various shop organizers. Its dimensional stability is paramount here. A jig or fixture needs to remain accurate over time and through changes in humidity; Baltic Birch delivers on this. You can build a crosscut sled, a router table fence, or intricate assembly jigs with the confidence that they will maintain their shape and precision.

The hardness and wear resistance of birch veneer also contribute to its suitability for shop projects. Jigs and fixtures often see repeated use and can be subject to knocks and bumps. Baltic Birch Plywood can withstand this wear and tear better than softer plywood options. Its smooth face allows workpieces to slide easily, and its strength means you can incorporate T-tracks, clamps, and other hardware securely.

Moreover, the void-free core and consistent thickness of Baltic Birch Plywood make it a pleasure to machine. It cuts cleanly with minimal tear-out (especially with appropriate blades and techniques), drills precisely, and routes smoothly. This allows for the creation of very accurate and reliable shop aids. Many woodworkers will buy full sheets of BB/BB grade Baltic Birch specifically for outfitting their shop because it offers the best combination of performance, durability, and a reasonably clean appearance for these utilitarian but critical tools.

Baltic Birch Plywood vs. Standard Plywood: What are the Key Differences in Grade and Performance?

When we talk about "standard" plywood, it often refers to construction-grade plywood made from softer woods like pine or fir, or even some hardwood plywood that doesn't share the specific construction of Baltic Birch. The differences are quite significant, impacting both grade (appearance) and performance.

Ply Count and Core Material:

- Baltic Birch Plywood: Features numerous, thin, all-birch hardwood veneer plies. For example, an 18mm (3/4") sheet can have 13 plies.

- Standard Plywood: Typically has fewer, thicker plies. The core plies might be made from softer wood species, even if the face veneer is hardwood. This can vary greatly by product.

Presence of Voids:

- Baltic Birch Plywood: Known for its void-free or virtually void-free core. This means no gaps or air pockets within the inner plies.

- Standard Plywood: More likely to contain voids in the core, especially in lower grades. These voids can weaken the panel, affect screw holding, and create an unsightly edge.

Strength and Stability:

- Baltic Birch Plywood: The multi-ply, all-hardwood construction and void-free core give it superior strength, stiffness, and dimensional stability. It resists warping and twisting exceptionally well.

- Standard Plywood: Strength and stability can vary widely depending on the grade and materials used. Generally, it won't match Baltic Birch in these aspects, especially if it has a softer core or voids.

Edge Appearance:

- Baltic Birch Plywood: Offers an attractive, uniform, and dense layered edge that can be left exposed and finished.

- Standard Plywood: The edge is often less appealing, may show voids, and typically requires edge banding or other treatments for a finished look.

Grading and Face Quality:

- Baltic Birch Plywood: Has its own specific grading system (B, BB, CP, C) that focuses on the quality of the birch face veneer, including the presence and type of knots and patches.

- Standard Plywood: Uses different grading systems (e.g., A, B, C, D for appearance, or structural ratings). The quality and consistency of the face veneer can be less predictable, especially in utility grades.

While standard plywood certainly has its place and is often more budget-friendly for general construction, Baltic Birch Plywood is a premium product chosen when performance, stability, and a high-quality appearance (especially the edge) are paramount. It's a step up, much like choosing high-quality Phenolic film faced plywood 16mm for concrete formwork when a smooth finish and many reuses are needed.

Where Can I Find Full Sheets of Quality Baltic Birch Plywood? Tips for Sourcing.

Sourcing high-quality Baltic Birch Plywood, especially in full sheets, can sometimes be a challenge depending on your location and whether you're a hobbyist or a large-scale business. For individual woodworkers or small shops, a local woodworkers source or specialized lumberyard is often the first place to check. These retailers may stock common sizes and grades, though their selection might be limited. Building relationships with staff at a good local store can be beneficial, as they might be able to special order specific grades or thicknesses.

For businesses like Mark Thompson's, requiring larger quantities and consistent supply, sourcing directly from manufacturers or reputable importers becomes more viable. This is where companies like ours, Jsylvl, come in. As a factory, we can ensure consistent quality control from raw material selection to the final product. When sourcing Baltic Birch Plywood, especially in B2B transactions, it's critical to:

- Specify the Grade Clearly: Be precise about the grade you need (e.g., BB/BB, B/CP) for both the face and back veneer. Misunderstandings here can lead to receiving a product that doesn't meet your aesthetic or performance requirements.

- Verify Certifications: If your project requires it (e.g., for LEED points or specific market regulations), ask for certifications like FSC (Forest Stewardship Council) to ensure sustainable sourcing, or CARB compliance for formaldehyde emissions. Always verify the authenticity of these certificates.

- Discuss Quality Control: Understand the supplier's quality control processes. How do they ensure minimal voids, consistent thickness, and accurate grading? Don't hesitate to ask for sample pieces or detailed specifications.

- Clarify Logistics and Lead Times: For international orders, clear communication about shipping, lead times, and incoterms is essential to avoid delays that can impact project schedules – a key concern for many procurement officers.

Finding a reliable supplier, whether it's a local shop or an online international manufacturer, is key to getting the Baltic Birch Plywood your project deserves. Look for transparency, good communication, and a willingness to discuss your specific needs. Many woodworkers also find excellent deals and product variety by searching online, but be sure to vet the seller's reputation and understand shipping costs, as plywood sheets can be expensive to ship.

What Should I Inspect When Receiving My Baltic Birch Plywood Order?

Once your Baltic Birch Plywood arrives, a thorough inspection is crucial before you accept the delivery or start cutting into the sheets. This step can save you a lot of headaches down the line, especially if you've ordered a significant quantity. As someone who oversees production, I know that even with the best quality control, issues can occasionally arise during transit or handling.

Here’s what to look for:

- Count and Dimensions: First, ensure you received the correct number of sheets and that they match the size and thickness you ordered. Use calipers to check the actual thickness in several spots on a few sheets to ensure consistency.

- Face Veneer Quality: Carefully examine the face and back veneers of each sheet (or a representative sample if it's a large order).

- Does the quality match the grade you paid for? Look for the expected number and type of knots, patches, and color variations. For example, if you ordered B/BB, the B face should be very clear, while the BB face can have neat patches.

- Check for any shipping damage: dents, deep scratches, or broken corners.

- Edge Inspection: The edge of Baltic Birch Plywood is one of its selling points. Examine it for:

- Voids: While true Baltic Birch should be virtually void-free, look closely. Occasional very small imperfections in the inner plies might be acceptable depending on the grade, but significant or frequent voids are a red flag.

- Delamination: Ensure all plies are securely glued together. There should be no signs of layers separating.

- Flatness: Lay a sheet on a known flat surface or sight down its length and width. While some minor bowing can occur with changes in humidity (especially in thinner sheets), excessive warping or twisting could indicate a problem with the material or improper storage.

- Moisture Content (if possible): If you have a moisture meter, checking the moisture content can be insightful, especially if you're in a very different climate than the plywood's origin. It should be acclimated to your shop environment before use anyway, but unusually high moisture could be a concern. This is a frequent pain point for buyers like Mark Thompson, as high moisture can lead to warping or mold.

Document any issues immediately with photographs and contact your supplier. A reputable seller or factory will work with you to resolve legitimate quality concerns. This diligence in inspection helps ensure your project starts with the best possible material.

Are There Specific Techniques for Cutting and Finishing Baltic Birch Plywood?

Working with Baltic Birch Plywood is generally a pleasure due to its quality, but a few specific techniques can help you get the best results, especially when cutting and finishing.

Cutting:

- Blade Choice: To minimize tear-out on the face veneer, especially the top face during a table saw cut, use a sharp, high-quality plywood blade with a high tooth count (typically 60-80 teeth for a 10-inch blade) and an Alternate Top Bevel (ATB) or High Alternate Top Bevel (Hi-ATB) tooth geometry.

- Zero-Clearance Insert: Using a zero-clearance insert on your table saw or a splinter guard on your track saw will provide support to the wood fibers right at the cut line, significantly reducing tear-out on the bottom face.

- Scoring Cut: For the cleanest possible cuts, especially on critical pieces, you can make a shallow scoring cut (just 1-2mm deep) first, then make the full-depth cut. This is particularly effective for crosscuts.

- Painter's Tape: Applying painter's tape along the cut line can also help reduce chipping on the face veneer.

- Router Bits: When routing Baltic Birch, use sharp, high-quality bits. Climb cutting (with caution and experience) can sometimes produce a cleaner edge on certain operations, but conventional cutting with a fresh bit usually yields excellent results.

Finishing:

- Sanding: Baltic Birch Plywood typically arrives with a fairly smooth face, but light sanding is recommended before applying a finish. Start with a finer grit, like 180 or 220, as the veneer is thin and aggressive sanding can wear through it. Always sand with the grain.

- Edge Finishing: The multi-ply edge is often a design feature. To highlight it:

- Sand the edges smooth, progressing through grits up to 220 or higher.

- A slight chamfer or round-over with a router or sandpaper can make the edge more durable and feel better.

- Clear finishes like polyurethane, lacquer, or hardwax oil look fantastic on the edges and face.

- Staining: Baltic Birch can be stained, but like all birch, it can be prone to blotching. Using a pre-stain wood conditioner is highly recommended for a more uniform color. Gel stains also tend to work better than highly liquid penetrating stains.

- Painting: If painting, a good quality primer is essential to seal the wood and ensure good adhesion and an even topcoat. The smooth surface of Baltic Birch makes for an excellent paintable surface.

By paying attention to these details, you can achieve professional-quality results that showcase the inherent beauty and precision of Baltic Birch Plywood. As a manufacturer, we also produce items like OSB board 18mm, which has different working characteristics, underscoring the importance of tailoring techniques to the specific engineered wood product.

What are the Common Concerns When Using Baltic Birch Plywood, and How Can They Be Addressed?

While Baltic Birch Plywood is a fantastic material, there are a few common concerns or potential downsides that users, especially those like Mark Thompson who procure materials for large projects, should be aware of. Understanding these can help in planning and sourcing.

- Cost: Let's be upfront – Baltic Birch Plywood is generally more expensive than standard plywood or other sheet goods like MDF or particleboard. Its quality, all-hardwood construction, and often imported nature contribute to its higher price point.

- Addressing it: Evaluate if the specific benefits (strength, stability, void-free core, attractive edge) justify the cost for your particular project. For high-visibility items, furniture, or precision jigs, the investment is often well worth it. For hidden structural parts or utility applications, a more economical plywood might suffice.

- Availability and Sourcing: Depending on your local market, finding a consistent supply of various grades and thicknesses of Baltic Birch Plywood can sometimes be challenging. The 5'x5' sheet size might also require adjustments in planning if you're used to 4'x8' sheets.

- Addressing it: Plan ahead, especially for larger projects. Build relationships with reliable suppliers. For businesses, exploring direct import from factories like Jsylvl can ensure a more stable supply chain and potentially better pricing on bulk orders, although this involves more complex logistics and longer lead times.

- Verifying Authenticity and Grade: Because it's a premium product, there's always a risk of encountering materials falsely marketed as "Baltic Birch" or misrepresenting the grade. The term "birch plywood" is not the same as "Baltic Birch Plywood."

- Addressing it: Buy from reputable dealers or manufacturers. Ask for detailed specifications and, if possible, samples. Understand the grading system (B, BB, CP, C) and inspect the material carefully upon arrival. For critical applications, requesting mill certifications or third-party testing reports can provide additional assurance. As a supplier, we believe in transparency and providing all necessary documentation for our High Quality LVL, Plywood, and OSB Flooring Supplier | Jsylvl.

- Thin Face Veneer: The face veneer on Baltic Birch Plywood, while high quality, is relatively thin. Aggressive sanding or mishandling can lead to sanding through the top ply.

- Addressing it: Use caution when sanding. Start with finer grits (180-220) and avoid excessive pressure or prolonged sanding in one spot. Power sanders should be used with care.

- Sustainability Concerns (if not certified): As with any wood product, the source of the birch wood is important.

- Addressing it: Look for FSC (Forest Stewardship Council) or PEFC (Programme for the Endorsement of Forest Certification) certified Baltic Birch Plywood. This ensures the wood comes from responsibly managed forests. Many reputable suppliers will offer certified options.

By being aware of these potential concerns, you can make more informed decisions and take steps to mitigate any risks, ensuring your experience with Baltic Birch Plywood is a positive one.

As a Plywood Factory, How Do We Ensure the Quality of Our Baltic Birch Plywood?

From my perspective as Allen, representing a factory that takes pride in its engineered wood products, ensuring the quality of any plywood, including a premium product like Baltic Birch (if we were to produce it to its specific definition, or a comparable high-quality birch plywood), involves a meticulous, multi-stage process. This is crucial for meeting the expectations of discerning customers like Mark Thompson, who prioritize quality and reliability.

First, it begins with raw material selection. For a product aspiring to Baltic Birch quality, this means sourcing high-grade birch logs and ensuring the veneer peeled from these logs is consistent in thickness and largely free from defects that would compromise the integrity of the inner plies or the appearance of the face veneer. The quality of the glue is also paramount; we use adhesives that provide strong, durable bonds and, where required, meet specific emission standards (e.g., E0, CARB P2).

The lamination process is a critical control point. Each veneer sheet must be laid up correctly, with alternating grain directions, and the glue spread must be uniform and precise. The pressing stage, involving specific temperature and pressure parameters, ensures a solid bond throughout the panel, eliminating voids and creating that dense, stable core characteristic of high-quality plywood. We invest in modern machinery and skilled operators to maintain tight tolerances during these stages. For instance, the precision required for our LVL (Laminated Veneer Lumber) products, often used in structural applications, translates to a culture of exactness across all our plywood lines.

Finally, rigorous quality control (QC) checks are implemented at various points and on the final product. This includes:

- Visual Inspection: Checking face and back veneers against established grade standards for knots, patches, discoloration, and other characteristics.

- Dimensional Accuracy: Verifying thickness, length, width, and squareness of each sheet or batch.

- Bond Quality Tests: Performing tests (e.g., boil tests, knife tests) to ensure the plies are securely laminated and won't delaminate under stress or moisture.

- Moisture Content Monitoring: Ensuring the plywood is dried to the appropriate moisture content to prevent warping and ensure stability.

- Void Detection: For premium grades, specialized checks or even random destructive testing might be employed to confirm the integrity of the inner plies.

By adhering to these stringent processes, a factory can consistently produce Baltic Birch Plywood (or a comparable high-quality birch plywood) that meets the high standards expected for demanding applications in furniture, cabinetry, and precision shop projects. This commitment to quality is what builds trust with B2B clients who rely on us for consistent and reliable building materials.

Key Takeaways on Baltic Birch Plywood:

- Superior Construction: Made with multiple, thin, all-birch hardwood veneers for exceptional strength, stability, and a void-free core.

- Distinct Grading: Understand grades like B/BB, BB/BB, BB/CP to select the right face quality for your project, considering patches and knots.

- Common Sizes: Typically found in 5'x5' sheets with metric thicknesses (e.g., 3mm, 6mm, 12mm, 18mm). Always verify "actual" thickness.

- Ideal Applications: Excellent for high-quality cabinetry, furniture, drawer sides, jigs, fixtures, and any project requiring precision and a beautiful exposed edge.

- Sourcing: Can be found at local woodworkers source retailers or, for bulk B2B needs, through direct importers or manufacturers like Jsylvl.

- Quality Checks: Inspect for correct grade, dimensional accuracy, edge quality (no voids), flatness, and potential shipping damage upon arrival.

- Working Tips: Use sharp, high-tooth-count blades and zero-clearance inserts for clean cuts. Pre-stain conditioner is recommended if staining.

- Key Advantages: Strength, stability, screw-holding, attractive multi-ply edge, and excellent machinability.

- Considerations: Higher cost, potential availability issues for certain grades/sizes, and the importance of verifying authenticity and certifications (e.g., FSC).

By understanding these aspects of Baltic Birch Plywood, you're well-equipped to harness its unique benefits for your next woodworking or construction endeavor.

Post time: May-20-2025