Have you ever looked at a beautifully curved reception desk, a rounded wall feature, or elegantly shaped furniture and wondered how they achieved those smooth bends with wood? The secret often lies in a remarkable material: bending plywood, also known as flexible plywood or bendy ply. This isn't your standard rigid sheet of plywood; it's engineered specifically to bend and conform to tight curves, opening up a world of design possibilities that are difficult or impossible with conventional wood products.

Understanding how flexible plywood works, its different types, and how to use it effectively can be a game-changer for construction companies, furniture makers, and designers like Mark Thompson in the USA, who are always looking for innovative and cost-effective materials. As Allen from Jsylvl, a specialized factory in China exporting engineered wood products like LVL Timber and various plywood types globally, I've seen firsthand how this versatile product solves complex design challenges. This article will guide you through everything you need to know about bending plywood, from its unique construction to practical application tips, helping you achieve stunning curved results reliably and efficiently. Stick around to learn how to incorporate this amazing material into your next project.

What Exactly is Bending Plywood (Flexible Plywood)?

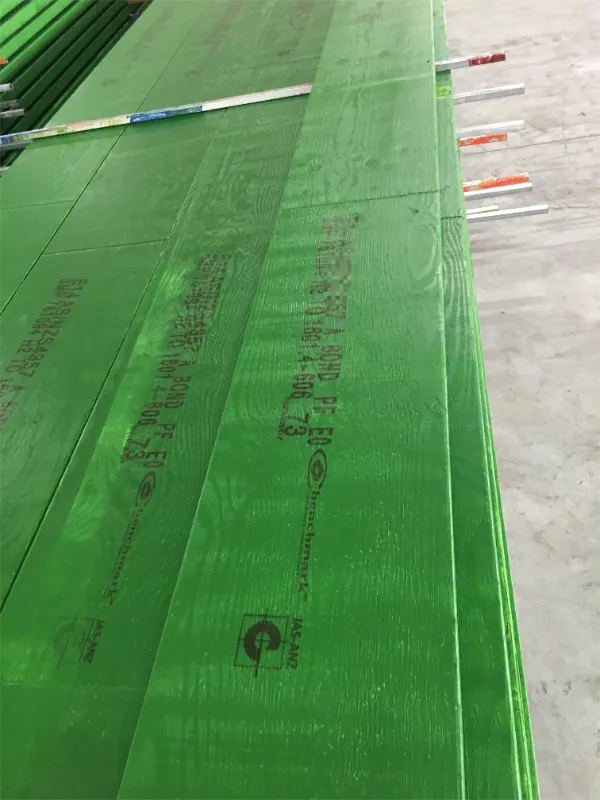

Bending plywood, often called flexible plywood or "bendy ply," is a specialized type of engineered wood sheet designed specifically to bend easily into curved shapes. Unlike standard plywood which is rigid and strong in flat planes, bending plywood is constructed to offer significant flexibility along one axis. Think of it as a wood panel that loves to curve! It allows architects, designers, and builders to create smooth, rounded surfaces without the complex joinery, steaming, or kerf cutting often required with solid wood or standard ply.

This unique product is typically made from tropical hardwood veneers known for their pliability, bonded together with adhesives under heat and pressure, much like conventional plywood. However, its core difference lies in the construction (which we'll explore next) that allows it to conform to a predetermined radius without cracking or splitting. This makes it an ideal material for wrapping columns, creating curved walls, building arched doorways, or crafting custom furniture with rounded elements. It provides a stable and smooth surface ready for finishing, painting, or applying laminate or veneer.

The primary advantage of using bending plywood is the ease and speed with which complex curves can be formed. It saves labor time and reduces material waste compared to other methods of achieving curves. For businesses like Mark Thompson's, which focus on efficiency and cost-effectiveness while demanding quality, understanding and utilizing bending ply can offer a significant competitive edge in delivering sophisticated design elements within budget and schedule. It truly is a problem-solving material in the world of construction and design.

How is Bendy Ply Made to Be So Flexible?

The secret to the remarkable flexibility of bending plywood lies in its unique construction, specifically the arrangement and type of wood veneers used. Standard plywood gains its strength and rigidity from alternating the grain direction of each veneer layer by 90 degrees. This cross-graining creates a strong, stable sheet resistant to bending and warping. Bending plywood, however, takes a different approach.

To achieve its ability to bend, flexible plywood is typically constructed with all, or most, of the veneer layers running in the same direction. Usually, it consists of two thin face veneers and a thicker central core layer made from a more pliable wood species, like Poplar or certain tropical hardwoods. The grains of all these layers are oriented parallel to each other, running either along the length (long grain) or across the width (cross grain) of the sheet. This parallel grain structure eliminates the inherent stiffness of cross-banded plywood, allowing the panel to flex easily in one specific direction.

Furthermore, the type of wood used for the veneers plays a crucial role. Manufacturers select species known for their ability to bend without fracturing. The adhesives used are also important, needing to hold the layers together firmly while still allowing the necessary movement for bending. The result is a product that feels somewhat "floppy" compared to standard ply, ready to be coaxed into a smooth, consistent curve around a form or framework. This intentional engineering makes bending ply an incredibly useful material for achieving otherwise difficult shapes.

What are the Different Types of Bending Plywood? (Long Grain vs. Cross Grain)

Bending plywood comes primarily in two distinct types, defined by the direction the wood grain runs relative to the dimensions of the sheet, and consequently, the direction in which the panel will bend most easily. Understanding this difference is critical for selecting the right product for your specific application.

-

Long Grain Bending Plywood: In this type, the wood grain of the veneers runs parallel to the longest dimension of the sheet (typically the 8-foot direction in a standard 4x8 sheet). This means the plywood will bend most easily along its length, forming a curve perpendicular to the long edge. This is often referred to as a "barrel bend" because if you were to bend it fully, it would form a cylinder with its height determined by the shorter dimension (the 4-foot width). Long grain bendy ply is ideal for applications like covering curved walls or creating cylindrical columns where the height of the curve is the shorter dimension of the sheet.

-

Cross Grain Bending Plywood: Conversely, in cross grain (or short grain) bending plywood, the wood grain runs parallel to the shortest dimension of the sheet (the 4-foot direction in a 4x8 sheet). This allows the plywood to bend most easily along its width, forming a curve perpendicular to the short edge. This is sometimes called a "column bend" because it's suited for wrapping around columns or creating curved structures where the height of the curve corresponds to the longer dimension (the 8-foot length) of the sheet.

Here's a simple table summarizing the key difference:

| Type | Grain Direction (on 4x8 sheet) | Bends Easiest Along... | Typical Use | Bend Type Terminology |

|---|---|---|---|---|

| Long Grain | Parallel to 8' side | 8' Length | Curved Walls, Soffits | Barrel Bend |

| Cross Grain | Parallel to 4' side | 4' Width | Columns, Rounded Ends | Column Bend |

Choosing between long grain and cross grain depends entirely on how you need the sheet to bend for your project. Always confirm the grain direction before ordering or using the material to ensure it matches your design requirements. Using the wrong type will make bending difficult and could lead to cracking or an uneven surface.

Can You Bend Regular Plywood? Why Choose Flexible Ply?

It's a common question: can you force regular plywood into a curve? The answer is yes, but with significant limitations and risks. Standard plywood, like structural ply or even Non Structural Plywood, is designed for rigidity. Its cross-laminated veneer layers resist bending. While you can sometimes bend thin sheets of regular plywood (like 1/4 inch or 6mm) over a very large radius, attempting tighter curves usually leads to problems. You risk snapping the sheet, causing surface veneers to crack or splinter, or creating flat spots instead of a smooth curve.

Methods exist to encourage regular plywood to bend, such as steam bending or kerf cutting. Steam bending involves exposing the wood to hot steam to make it pliable, then clamping it to a form until it dries – a time-consuming and equipment-intensive process. Kerf cutting involves making a series of parallel cuts (kerfs) partway through the thickness of the plywood on the inside face of the bend. These kerfs allow the sheet to close up and form a curve. However, kerf bending significantly weakens the panel, requires careful calculation of cut depth and spacing, and often leaves a faceted rather than perfectly smooth surface that needs filling and sanding.

This is precisely why bending plywood was developed. It eliminates the need for these complex and often unsatisfactory methods. Flexible plywood is engineered to bend easily and smoothly to a much tighter radius without steaming or kerf cutting. It maintains its structural integrity (within its intended non-structural use) and provides a consistent, uniform curve. For applications requiring smooth, reliable curves – like architectural features, furniture, cabinetry, or retail displays – bending ply offers a far superior solution in terms of speed, ease of use, quality of finish, and overall cost-effectiveness. It's the purpose-built product for the job.

What is the Smallest Radius Bending Plywood Can Achieve?

One of the most critical factors when working with bending plywood is understanding its minimum bending radius. This refers to the tightest curve the sheet can conform to without sustaining damage like cracking, splintering, or buckling. Trying to force the material into a curve tighter than its minimum recommended radius is a recipe for failure and wasted product.

The minimum bending radius isn't a single fixed value; it primarily depends on two factors:

- Thickness of the Plywood: Thinner sheets can naturally bend to a tighter radius than thicker sheets. Common thicknesses for bending plywood range from 3mm (about 1/8 inch) up to around 9mm or 12mm (about 3/8 to 1/2 inch). A 3mm sheet might achieve a radius as small as 5-7 inches, while a thicker 9mm sheet might have a minimum radius closer to 10-12 inches or more.

- Grain Direction (Long vs. Cross): While both types are designed to flex, the minimum radius can sometimes vary slightly depending on whether it's a long grain or cross grain panel and the specific wood species used in its manufacture.

It's crucial to consult the manufacturer's specifications for the specific bending plywood product you are using. Reputable suppliers like Jsylvl provide technical data sheets detailing the minimum bending radius for each thickness and type they offer. As a general rule of thumb, you can often estimate the minimum radius to be roughly 75 to 100 times the thickness of the panel, but always defer to the manufacturer's official guidelines. For extremely tight curves, using multiple layers of thinner bending ply laminated together over a form is often a better approach than trying to force a single thick sheet beyond its limits.

How Do You Work With Bending Plywood Sheets? (Cutting, Shaping, Joining)

Working with bending plywood is relatively straightforward, sharing many techniques with standard plywood, but with special consideration for its flexible nature. Here’s a breakdown of key aspects:

Cutting: You can cut bending plywood using standard woodworking tools like circular saws, table saws, or jigsaws. Use fine-toothed blades designed for plywood or veneers to minimize splintering on the exit side of the cut. Supporting the sheet properly during cutting is important due to its flexibility; ensure it lies flat or is clamped securely to prevent vibration or binding. Score the cut line first with a utility knife, especially on the face veneer, to help achieve a cleaner edge.

Shaping and Bending: The key is to bend the plywood slowly and evenly over a curved form or framework. This form could be made from MDF, particle board, or built-up ribs.

- Direction: Always bend the plywood perpendicular to the grain direction specified (i.e., barrel bend for long grain, column bend for cross grain). Attempting to bend it parallel to the grain will likely cause it to crack.

- Securing: Use clamps, straps, or even vacuum bags to hold the bending ply securely against the form while the adhesive cures (if laminating multiple layers or attaching to a structure). Start securing from the center of the curve and work outwards towards the edges to ensure even pressure and prevent air pockets.

- Multiple Layers: For thicker or stronger curved elements, it's common practice to laminate two or more layers of thin bending plywood together. Apply a suitable wood adhesive (like PVA glue or epoxy) evenly between the layers, then clamp them to the form until the glue fully cures. This method allows for tighter radii and creates a more rigid final shape.

Joining: Bending plywood sheets can be joined edge-to-edge or end-to-end using standard woodworking techniques.

- Butt Joints: Simple butt joints secured with glue and potentially biscuits or dowels can work, especially if backed by a supporting structure.

- Scarf Joints: For a stronger and less visible join along the length or width, a scarf joint (an angled cut creating overlapping surfaces) is recommended, though requires more precision.

- Fasteners: Screws or staples can be used, but pre-drilling is highly recommended to prevent splitting the thin veneers. Ensure fasteners are compatible with the final finish and consider countersinking.

Always handle bending plywood carefully to avoid damaging the thin face veneers. Store sheets flat in a dry environment until ready for use. With a little practice, working with this versatile material becomes intuitive, enabling the creation of impressive curved forms.

What are Common Applications for Flexible Plywood in Construction and Design?

The ability of bending plywood to create smooth, consistent curves makes it a valuable material across a wide range of applications in both commercial and residential construction, as well as in furniture and fixture manufacturing. Its versatility allows designers and builders to move beyond straight lines and sharp corners, introducing organic shapes and unique architectural features.

Here are some common uses for flexible plywood:

- Curved Walls and Partitions: Creating rounded or serpentine walls in lobbies, offices, retail spaces, or homes. Long grain bendy ply is often used here.

- Column Encasements: Wrapping structural steel posts or concrete columns to provide a smooth, paintable, or veneer-ready cylindrical surface. Cross grain is typically preferred for this.

- Arched Doorways and Ceilings: Forming the curved soffits or reveals for arched openings or creating barrel-vaulted or domed ceiling features.

- Reception Desks and Counters: Building custom curved fronts for reception desks, bars, information counters, and retail displays. This is a very popular application.

- Curved Cabinetry and Furniture: Manufacturing furniture with rounded corners, curved cabinet doors (cabinet carcasses), round table aprons, or uniquely shaped seating. The ability to create consistent curves easily is a major benefit for furniture makers.

- Stage Sets and Exhibition Stands: Quickly building curved backdrops, display units, and structural elements for theatrical productions or trade show booths where unique shapes are desired.

- Skateboard Ramps: While thicker materials are often used for the main surface, thinner bending ply can be used in multiple layers to form the transition curves.

- Boat Building (Interior): Used for curved interior cabinetry and fixtures where structural strength is not the primary requirement. (Note: For hulls or structural marine parts, dedicated marine plywood is essential).

Essentially, anywhere a smooth, non-structural curve is required in a wood-based project, bending plywood offers an efficient and effective solution. Its ease of use compared to traditional bending techniques makes complex designs more accessible and affordable.

Tips for Getting the Best Results When Using Bending Ply?

Achieving professional-looking results with bending plywood is straightforward if you follow some best practices. As someone involved in the manufacture and supply of these products, like us at Jsylvl, we want our customers like Mark Thompson to succeed with our materials. Here are some key tips:

- Know Your Grain Direction: Double-check whether you have long grain or cross grain bending ply and ensure you are bending it in the correct direction (perpendicular to the grain). This is the single most common mistake beginners make.

- Respect the Minimum Radius: Don't try to force the plywood into a curve tighter than the manufacturer recommends for that specific thickness. If a very tight radius is needed, use thinner sheets or laminate multiple layers.

- Use a Solid Form/Jig: Bending over a well-built, smooth, and accurate form or framework is crucial for achieving a consistent curve. The bending ply will conform to the shape it's pressed against. Ensure the form is slightly over-bent to account for any potential spring-back.

- Bend Slowly and Evenly: Apply pressure gradually and uniformly across the width of the bend. Avoid sudden or localized force, which can cause ripples or cracks. Start clamping/securing from the center of the curve and work outwards.

- Acclimatize the Material: Allow the bending plywood sheets to adjust to the temperature and humidity of your workshop for 24-48 hours before bending, especially if conditions differ significantly from where it was stored. This minimizes stress during bending.

- Consider Two Layers: For most applications, especially those requiring more rigidity or a perfectly smooth two-sided finish, laminating two layers of bending plywood back-to-back (with adhesive) over the form is standard practice. This creates a stable, balanced panel. You can orient the grain directions opposite if desired, though often they are kept the same.

- Proper Adhesive Application: If laminating layers, ensure even coverage of a suitable wood glue (PVA, polyurethane, or epoxy depending on the application and desired rigidity/water resistance). Avoid excessive glue that causes difficult cleanup, but ensure no dry spots.

- Sufficient Clamping: Use enough clamps or a vacuum bag to apply firm, even pressure across the entire curved surface while the glue cures. Leave it clamped for the full recommended curing time.

- Finishing: Once formed and cured, the surface of bending plywood can be lightly sanded (use fine grit paper and be careful not to sand through the thin face veneer) and then painted, stained, veneered, or laminated like standard plywood.

Following these tips will help ensure your curved projects using flexible plywood turn out smooth, strong, and exactly as you envisioned.

Is Flexible Plywood Structurally Sound?

This is a critical point to understand: Bending plywood is generally considered a non-structural panel. Its unique construction, designed for flexibility, means it does not possess the same rigidity, strength, or load-bearing capacity as standard structural plywood (like 15mm Structural Plywood F11) or other engineered wood products like laminated veneer lumber LVL beams E13.2.

The parallel grain structure that allows it to bend easily also means it has significantly less strength across the grain. It's designed primarily for decorative or shaping purposes – creating curved surfaces that will be supported by an underlying framework or structure, or used in applications like furniture where loads are minimal. You would not typically use bending plywood for floor underlayment, roof sheathing, structural beams, or wall bracing where specific load-bearing capacities are required by building codes.

However, when used correctly – often by laminating two layers together over a supportive form – the resulting curved element can be quite stable and durable for its intended application. The lamination process creates a thicker, more rigid curved panel. The key is to rely on the supporting structure (ribs, framework, backing panel) for the primary strength, while the bending plywood provides the smooth, curved surface or skin. Always ensure your design incorporates adequate support for the curved elements made with flexible plywood.

Where Can I Source High-Quality Bending Plywood?

Finding a reliable supplier is crucial when purchasing specialized materials like bending plywood. Consistency in thickness, quality of veneer, adherence to minimum bending radius specifications, and reliable grain direction are essential for predictable results and minimizing waste. For procurement professionals like Mark Thompson, sourcing directly from a knowledgeable and reputable factory can offer advantages in terms of quality control, potential cost savings, and access to a wider range of products and custom options.

As a factory based in China, Jsylvl specializes in manufacturing and exporting a comprehensive range of engineered wood products, including bending plywood. We understand the specific requirements for producing high-quality flexible plywood suitable for demanding applications in markets like the USA, Europe, and Australia. We control the entire manufacture process, from selecting appropriate veneers to pressing and finishing the sheets, ensuring consistent quality batch after batch.

When looking for suppliers, consider factors beyond just price:

- Product Specifications: Do they clearly state the thickness, dimensions, grain direction (long or cross), and minimum bending radius?

- Quality Control: What measures do they have in place to ensure consistent quality and grading? Can they provide test reports or certifications if required?

- Experience & Expertise: Does the supplier understand the nuances of bending plywood and its applications? Can they offer technical support?

- Range of Products: Can they supply other necessary materials like standard plywood (Structural Plywood, Non-Structural Plywood), LVL Timber, or even finishing materials like Oak flooring? Sourcing multiple items from one supplier can simplify logistics.

- Logistics & Lead Times: Can they reliably ship to your location (e.g., the USA) within agreed timelines?

Attending industry exhibitions is a great way to meet suppliers face-to-face, inspect product samples, and discuss your specific needs. Online searches are also effective, but always verify the supplier's credentials and ask for references or case studies. Partnering with a factory like Jsylvl, which values long-term relationships and understands the needs of international buyers, can help ensure you receive high-quality bending plywood that performs exactly as expected for your curved design projects.

Key Takeaways on Bending Plywood:

- Purpose-Built for Curves: Bending plywood (flexible plywood) is specifically engineered to bend easily into smooth curves without cracking, unlike standard plywood.

- Construction is Key: Its flexibility comes from having most or all veneer layers oriented with the grain running in the same direction.

- Two Main Types: Choose Long Grain ("barrel bend") for curves along the sheet's length or Cross Grain ("column bend") for curves along the sheet's width.

- Know the Limits: Always adhere to the manufacturer's specified minimum bending radius for the given thickness to prevent damage.

- Use a Form: Bend the plywood slowly and evenly over a solid, smooth form or framework for consistent results.

- Laminate for Strength: Often, two layers are laminated together with adhesive over a form to create a more stable and rigid curved element.

- Non-Structural Use: Remember that bending plywood is primarily for decorative applications and creating curved surfaces; it relies on a supporting structure for strength.

- Versatile Applications: Ideal for curved walls, column wraps, arched ceilings, furniture, cabinetry, and displays.

- Source Wisely: Partner with reputable suppliers or factories like Jsylvl that provide clear specifications and consistent quality control for reliable performance.

Post time: Apr-28-2025