Birch plywood is a highly regarded engineered wood product, celebrated for its exceptional strength, smooth surface, and attractive appearance. Particularly favoured in furniture making and cabinetry, it offers a blend of durability and aesthetic appeal that few materials can match. This article delves into the specifics of birch plywood, including the renowned Baltic birch variety, exploring its quality attributes, durability, sourcing considerations, and wide range of applications. For procurement professionals like Mark Thompson, seeking reliable, high-quality wood panel products at competitive prices, understanding the nuances of birch plywood is crucial for making informed purchasing decisions and avoiding common pain points like inconsistent quality or shipping delays. Read on to discover why birch plywood, especially from a trusted source, is a go-to choice for demanding woodworking projects.

What Exactly is Birch Plywood and How is it Made?

Birch plywood is an engineered wood panel constructed from multiple thin layers, or plies, of birch veneer. These veneer sheets are carefully peeled from birch logs and then bonded together using strong adhesives under heat and pressure. The key to birch plywood's remarkable strength and stability lies in its construction process: each adjacent ply has its wood grain oriented perpendicular to the previous one, typically at a 90-degree angle. This cross-banded structure is fundamental, distributing stress across the panel, significantly reducing the risk of warping or splitting compared to solid wood, and enhancing its dimensional stability.

The result is a panel that is significantly stronger and more stable than a solid piece of wood of the same thickness. Birch plywood is known for its smooth surface, light color, and subtle, fine grain pattern, which makes it visually appealing and easy to finish. The birch veneers used are typically sourced from birch trees common in Northern Europe and North America. The precise number of plies varies depending on the thickness and grade of the birch plywood, but the layering technique ensures consistent performance and durability. This material is often used in applications where both strength and aesthetics are important.

The manufacturing process demands precision, from log selection and peeling the veneer to gluing and pressing. Quality control checks ensure consistent thickness, proper adhesion between plies, and minimal defect issues. High-quality birch plywood will have uniform veneer thickness and void-free cores, contributing to its overall structural integrity and finish quality. This attention to detail during production makes birch plywood a reliable material for various demanding uses.

Why is Baltic Birch Plywood Often Considered the Gold Standard?

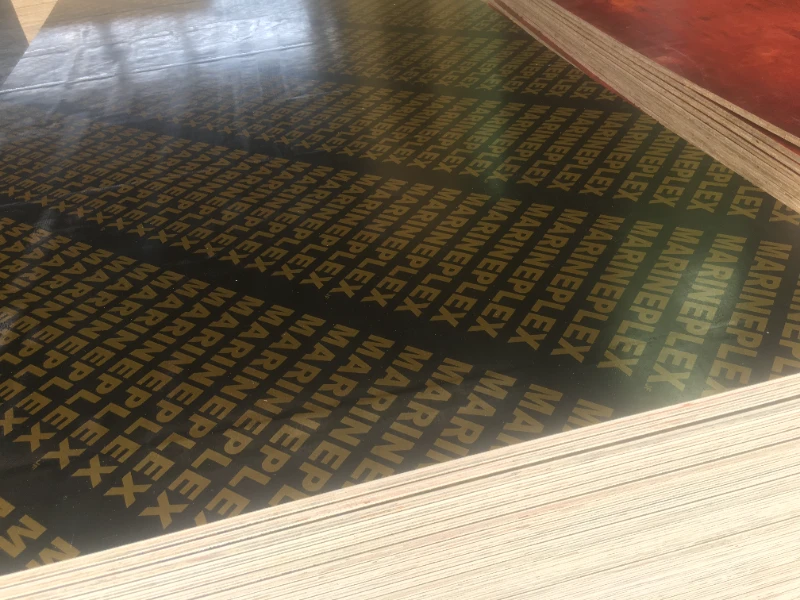

Baltic birch plywood represents a specific type of birch plywood primarily sourced from the Baltic Sea region (countries like Finland, Latvia, Estonia, and Russia). What sets it apart is its unique construction: unlike many standard plywoods that might use softer woods or fewer plies for the core, Baltic birch plywood is typically made entirely from birch veneers, including the core layers. Furthermore, these veneer layers are generally thinner and more numerous than those found in standard birch plywood of the same thickness. This multi-ply construction results in a panel with exceptional strength and stability, a denser core with fewer voids, and superior screw-holding capabilities.

Another defining characteristic of Baltic birch plywood is its aesthetically pleasing edge profile. Because all plies are birch veneer, the edges reveal attractive, uniform stripes when cut, which can be left exposed and finished for a decorative look in furniture designs and cabinetry. This eliminates the need for edge banding in many cases, simplifying the woodworking process. Standard birch plywood, while still a quality product, might have core veneers made from different, potentially softer species, which might not offer the same edge appearance or consistent density.

The commitment to quality in Baltic birch plywood production usually means stricter grading standards, resulting in face veneers with a cleaner, more uniform appearance and minimal defects. While it often comes at a higher price point than standard birch plywood, its superior mechanical properties, durability, stability, and aesthetic appeal make it the go-to choice for high-end cabinet making, furniture production, children's toys, jigs, fixtures, and other applications where precision and quality of birch plywood are paramount. For projects demanding the best, many woodworkers use Baltic birch.

How Can You Assess the Quality of Birch Plywood Before Purchasing?

Assessing the quality of birch plywood involves examining several key factors. Firstly, check the grade of the face veneers. Birch plywood comes in several grades (e.g., B/BB, BB/CP, CP/C), indicating the quality and appearance of the front (B) and back (BB) veneer faces. 'B' grade typically allows only minor natural characteristics like small pin knots, while 'BB' permits larger sound knots, patches, and slight discoloration. Lower grades (CP, C) allow for more significant defects. Understanding these grades helps match the plywood product to your project requirements, especially concerning visual appeal.

Secondly, inspect the edges of the birch plywood sheet. Look for uniformity in the ply layers. High-quality panels, especially Baltic birch plywood, will show consistent veneer thickness and minimal voids (gaps) within the core layers. Numerous voids can compromise the panel's structural integrity and make joinery more challenging. A dense, void-free edge indicates better manufacturing quality and contributes to the overall strength and durability of the birch plywood.

Finally, examine the overall flatness and consistency of the birch plywood sheet. It should lie flat without significant bowing or twisting. Check for uniform thickness across the panel. Also, inquire about the glue used (e.g., interior vs. exterior grade) and any relevant certifications (like CARB compliance for formaldehyde emissions or FSC for sustainable sourcing), especially important for interior design and safety-conscious applications. These checks help ensure you're getting a high-quality birch plywood panel suitable for your intended use.

What Contributes to the Impressive Durability of Birch Plywood Furniture?

The impressive durability of birch plywood furniture stems directly from its unique construction and the inherent properties of birch wood. The cross-banded layering of birch veneers creates a panel with exceptional strength that resists bending and sagging under load, which is crucial for shelves, tabletops, and structural components in furniture pieces. This layered structure effectively counteracts the natural tendency of wood to expand, contract, or warp with changes in humidity and temperature, giving birch plywood excellent dimensional stability.

Birch itself is a hardwood, naturally denser and stronger than softwoods like pine often used in lower-grade plywood cores. When multiple layers of this robust birch veneer are laminated together, the resulting birch plywood panel boasts significant impact resistance and can withstand considerable wear and tear, making it ideal for frequently used items like chairs, tables, and drawer boxes. The plywood's dense core also provides excellent screw-holding power, ensuring strong and lasting joinery in furniture making.

Furthermore, the smooth surface of birch plywood readily accepts various finishes, including paints, stains, and clear coats. A proper coating not only enhances the aesthetic appeal but also adds another layer of protection against scratches, spills, and moisture resistance, further extending the lifespan of the plywood furniture. The combination of a strong hardwood veneer, stable cross-banded construction, and excellent finish adherence makes birch plywood a highly durable and reliable choice for crafting long-lasting, high-quality furniture.

Where Does High-Quality Birch Plywood Typically Source From?

High-quality birch plywood, particularly the type favored for fine woodworking and furniture, predominantly originates from regions with abundant birch forests and established manufacturing expertise. The Baltic states (Estonia, Latvia, Lithuania), Finland, and Russia are the most renowned sources for premium Baltic birch plywood. These areas have vast forests of Betula pendula and Betula pubescens, the birch species typically used, and a long tradition of producing high-quality veneer and plywood products known for their multi-ply construction and consistent quality.

North America, specifically Canada and parts of the northern United States, is another significant source for birch plywood. While often differing in standard sheet size (e.g., 4x8 feet compared to the common 5x5 feet for Baltic) and sometimes in ply construction (potentially using fewer, thicker plies or different core materials), North American birch plywood still offers good quality, strength and durability, suitable for a wide range of applications including cabinetry and furniture. The birch veneer used here typically comes from Betula papyrifera (Paper Birch) or Betula alleghaniensis (Yellow Birch).

When sourcing birch plywood, the origin can be an indicator of certain characteristics (like ply count or standard dimensions), but quality ultimately depends on the specific manufacturer's standards and grading system. Reputable suppliers focus on sourcing logs sustainably, precise veneer peeling, careful ply lamination with quality adhesives, and rigorous quality control to minimize defect issues. Therefore, while region provides a clue, verifying the grade, construction, and certifications is crucial regardless of the source. As a factory like Jsylvl, we ensure our birch plywood meets stringent quality benchmarks expected by customers globally.

Is Birch Plywood Suitable for Both Structural Integrity and Visual Appeal?

Absolutely. Birch plywood is highly valued precisely because it excels in providing both structural integrity and visual appeal, making it incredibly versatile. Its cross-banded structure, utilizing strong birch veneers, gives it exceptional strength and stiffness, often exceeding that of solid wood of the same thickness, especially concerning resistance to bending across the grain. This makes it suitable for structural components in furniture making, casework, shelving systems, and even some construction applications where load-bearing capacity and stability are required. The inherent dimensional stability due to the multi-ply lamination minimizes issues like warping and twisting, ensuring parts maintain their shape over time.

Simultaneously, birch plywood offers significant aesthetic qualities. The face veneers typically have a light color and a fine grain pattern that is subtle yet attractive. This natural beauty can be showcased with a clear finish or easily enhanced with stain or paint. Higher grades of birch plywood present a smooth, clean surface with minimal defects, providing a premium look perfect for visible surfaces in high-quality furniture, cabinetry, and interior design elements. Even the edges, particularly on Baltic birch plywood, can be an attractive feature when left exposed.

This dual capability makes birch plywood a highly efficient material. Woodworkers and designers can use the same panel for both hidden structural parts and visible, aesthetically critical surfaces. This simplifies material sourcing and inventory management. The ability to achieve robust construction without sacrificing a beautiful finish is a key reason why birch plywood stands out as a preferred material in many woodworking disciplines, offering a reliable balance of form and function. It truly provides the best of both worlds for many projects.

What are the Key Advantages of Using Birch Plywood in Woodworking Projects?

Using birch plywood in woodworking projects offers a number of advantages that make it a popular choice among professionals and hobbyists alike. Firstly, its strength and stability are exceptional. The cross-banded construction resists warping, twisting, and seasonal movement far better than solid wood, ensuring that projects maintain their intended shape and structural integrity over time. This is particularly beneficial for large panels, doors, and intricate joinery.

Secondly, birch plywood provides excellent workability. It is easily cut, drilled, routed, and shaped using standard woodworking tools, often yielding cleaner cuts with less splintering compared to softer plywoods, thanks to the dense birch veneer. Its smooth surface requires minimal preparation before finishing, readily accepting paint, stain, varnish, or other coatings. The consistent density, especially in Baltic birch plywood, allows for secure fastening with screws and nails, contributing to strong, durable joints.

Thirdly, birch plywood offers great aesthetic appeal and versatility. Its light color and fine grain provide a clean, modern look suitable for various furniture styles, from modern to traditional. The attractive edge profile of multi-ply birch plywood can be incorporated into the design itself. Furthermore, it's generally more cost-effective than solid hardwood of comparable dimensions, especially for large panels, making complex or large-scale furniture projects more feasible. The combination of strength, stability, workability, and aesthetics makes birch plywood an efficient and reliable choice.

Here's a quick comparison table highlighting key advantages:

| Feature | Advantage Provided by Birch Plywood | Benefit for Woodworker |

|---|---|---|

| Construction | Cross-banded birch veneers | High strength and stability, less warp |

| Material | Dense hardwood (birch) | Durability, good screw holding |

| Surface | Smooth surface, fine grain | Easy finishing, attractive appearance |

| Workability | Easily cut, machined, joined | Efficient construction process |

| Edge Profile | Attractive multi-ply edge (esp. Baltic) | Can be left exposed, saves edge banding |

| Cost | Often more affordable than solid hardwood | Budget-friendly for larger projects |

| Consistency | Uniform thickness, fewer defects (in higher grades) | Reliable results, less material waste |

How Does Birch Plywood Compare Against Solid Birch Wood?

Comparing birch plywood to solid birch wood reveals distinct advantages and disadvantages for each, depending on the application. Birch plywood's primary advantage lies in its superior dimensional stability. The cross-banded ply construction counteracts wood's natural tendency to expand, contract, warp, or cup with changes in humidity. Solid birch, like all solid woods, is more susceptible to these movements, which can be problematic for large panels like tabletops or cabinet doors. Birch plywood offers greater consistency and reliability in maintaining its shape.

In terms of strength, birch plywood is generally stronger and stiffer across the panel width than solid birch of the same thickness, thanks to the alternating grain direction of the veneers. However, solid birch might offer greater strength along the grain and potentially better impact resistance in certain scenarios. Cost-wise, birch plywood is often more economical, especially for obtaining large, wide panels without the need for gluing up narrower solid boards, which also avoids visible glue lines inherent in solid wood panel construction.

Aesthetically, solid birch offers the continuous, uninterrupted grain pattern and natural characteristics of a single piece of wood, which some prefer for certain furniture styles. Birch plywood has a consistent but potentially less visually dynamic face veneer, and the layered edge profile is distinct (though often considered an attractive appearance in itself, especially with Baltic birch plywood). Finishing can be similar, though birch plywood might require care when sanding thin face veneers. Ultimately, the choice for furniture or cabinetry often depends on the specific requirements for stability, panel size, budget, and desired aesthetic appeal. Birch plywood is often the preferred choice for cabinets and large flat components due to its stability.

What Key Factors Should Buyers Evaluate When Sourcing Birch Plywood?

For buyers like Mark Thompson, sourcing birch plywood effectively requires careful evaluation of several key factors to ensure consistent quality and avoid project delays. First and foremost is Quality Inspection and Grading. Understand the grading system used by the supplier (e.g., B/BB, BB/CP) and clearly specify the required grade for face veneers based on the application's visibility requirements. Upon arrival, inspect samples or initial batches for consistency in veneer quality, smooth surface, absence of defects like excessive knots or patches (within grade limits), and importantly, check for voids in the core by examining the edges. Quality of birch plywood can vary, so establishing clear standards is vital.

Second, Certifications and Compliance are crucial. Verify necessary certifications relevant to your market and application. This might include CARB Phase 2 or EPA TSCA Title VI for formaldehyde emissions (especially for interior design in North America), FSC or PEFC for sustainable sourcing, and any specific structural ratings if the birch plywood is intended for load-bearing use. Request documentation and, if possible, independently verify the authenticity of certifications to mitigate risks, a common pain point related to sourcing from unfamiliar suppliers. This ensures compliance and enhances marketability. We, at Jsylvl, readily provide documentation for products like our Structural Plywood or Non-Structural Plywood options.

Third, Technical Specifications and Logistics must be confirmed. Specify and verify the exact dimensions (length, width, thickness) and tolerances. Discuss moisture content targets and how they are measured and maintained, as excessive moisture leads to warping and mold. Clarify ply count and core construction (e.g., solid birch veneer core vs. other materials), especially if sourcing Baltic birch plywood or similar high-spec panels. Finally, nail down lead times, shipping terms (Incoterms), packaging requirements to prevent damage, and reliable payment methods. Open communication with the supplier, like Allen here at Jsylvl, regarding these points minimizes surprises and ensures the sourced birch plywood meets expectations consistently. We understand the importance of reliable supply chains for engineered wood products, including our LVL Timber.

Beyond Furniture: What are the Other Common Applications for Birch Plywood?

While birch plywood is exceptionally popular in furniture making and cabinetry, its favourable properties lend themselves to a much broader wide range of applications. Its strength and lightweight nature make it suitable for certain structural uses, such as flooring underlayment, roof decking, and wall sheathing, particularly where a smooth, stable panel is desired. High-grade birch plywood is often specified for architectural elements, interior design features like wall paneling, and decorative beams where both aesthetics and performance matter.

In the realm of specialized woodworking, birch plywood, especially Baltic birch plywood, is a favourite for creating jigs, fixtures, and templates in workshops due to its stability, flatness, and ability to hold precise shapes. Its durability and smooth finish make it ideal for children's toys, puzzles, and educational materials. It's also used extensively in die-cutting boards (creasing matrix bases), skateboards (due to its flexural strength), and musical instrument components, such as drum shells, where its acoustic properties and ability to be molded are valued.

Furthermore, birch plywood finds use in transportation industries for vehicle interior linings and flooring, and in packaging for creating durable custom crates. Its consistent quality and reliability make it adaptable to various manufacturing processes. Whether needing a robust structural panel like our structural ply, or a fine surface for finishing similar to that found on some grades of our phenolic film faced plywood, the characteristics inherent in birch plywood make it a versatile and reliable material across many sectors beyond just furniture production. The material's adaptability is one of its strongest assets.

Key Takeaways on Birch Plywood:

- Construction: Birch plywood is made from thin layers of birch veneer glued together with alternating grain (cross-banded), providing superior strength and stability compared to solid wood.

- Baltic Birch: A premium type, typically with more, thinner, all-birch plies, known for its void-free core, attractive edge, and exceptional durability.

- Quality Factors: Assess grade (e.g., B/BB), edge voids, flatness, thickness consistency, glue type, and certifications (CARB, FSC).

- Durability: Comes from the strong hardwood (birch) veneer, stable cross-banded structure resisting warp, and good finish adherence enhancing moisture resistance.

- Advantages: Offers excellent stability, workability (easily cut & finished), aesthetic appeal (smooth surface, fine grain), and often better value than solid hardwood for large panels.

- Versatility: Ideal for furniture projects, cabinetry, drawer boxes, toys, jigs, architectural details, and even some structural applications due to its blend of strength and lightweight properties.

- Sourcing: Key regions include the Baltic states/Russia and North America. Buyers should verify specifications, quality, certifications, and logistics with suppliers.

Post time: Apr-18-2025