Birch wood is a remarkable natural material, prized for centuries for its unique combination of strength, beauty, and workability. As Allen from Jsylvl, a factory specializing in engineered wood products in China, I've seen firsthand the enduring appeal of birch and its various applications. This article will delve into the world of birch wood, exploring its characteristics, types, uses, and why it remains a popular choice for construction companies, furniture manufacturers, and woodworkers like our typical customer, Mark Thompson from the USA. Whether you're sourcing birch lumber for large-scale projects or seeking birch plywood for specific applications, understanding this hardwood is key to making informed decisions. We'll cover everything from its durability to its sustainability, helping you appreciate why birch is more than just a tree—it's a cornerstone of quality craftsmanship.

What Exactly is Birch Wood and Where Do Birch Trees Grow?

“What is birch wood?” is a common question we get. Simply put, birch wood comes from birch trees, which belong to the Betula genus in the Betulaceae family. These deciduous trees are predominantly found in the Northern Hemisphere, thriving in temperate and boreal climates across North America, Europe, and Asia. Here in China, we have access to various species of birch, which allows us to produce high-quality birch products for export. Birch trees grow relatively quickly, which is a factor in their sustainability.

The appearance of birch wood is one of its defining features. It typically has a pale, creamy white to light tan sapwood, often with a subtle grain pattern. The heartwood can be light brown or reddish-brown, though the sapwood is more commonly used. The texture of birch wood is generally fine and even, contributing to its smooth finish when sanded. The characteristic bark of many birch trees is also noteworthy, often papery and peeling, famously used by Native Americans for crafting canoes and containers. We frequently work with birch veneers, and the consistency of the grain makes it a reliable material for plywood and Laminated Veneer Lumber (LVL). The versatility of birch starts with its very nature.

Many people ask about the birch trees themselves. There are dozens of species of birch, each adapted to its specific environment. Some birch trees are relatively small, while others can grow quite tall, providing ample birch lumber. The environment where birch trees grow influences the wood's properties, but generally, birch wood is known for being sturdy and having good machining qualities. As a factory, we appreciate that birch is widely available, which helps in maintaining a consistent supply for our production lines, ensuring we can meet the demands of customers like Mark who rely on timely deliveries.

How Many Types of Birch Wood Are There, and What Are Their Key Differences?

When discussing types of birch wood, it's important to recognize that "birch" isn't a monolith. Several species of birch are commercially important, each with slightly different characteristics. Some of the most common types of birch wood you'll encounter include Yellow Birch (Betula alleghaniensis), White Birch (Betula papyrifera), Paper Birch (often synonymous with White Birch), Sweet Birch (Betula lenta), and Silver Birch (Betula pendula), which is more common in Europe. Yellow Birch is perhaps the most commercially significant in North America, known for its strength and light color. White Birch, with its iconic peeling bark, is also a popular choice, though generally a bit softer than Yellow Birch.

The differences between these types of birch wood primarily lie in their density, hardness, color, and grain patterns. For example, Yellow Birch tends to be harder and stronger, making it excellent for furniture, cabinetry, and even flooring. Its birch wood is often heavier. White Birch is somewhat lighter and softer, making it easy to work with for decorative items, plywood, and smaller woodworking projects. Sweet Birch has a darker, reddish-brown heartwood and was historically used as a substitute for mahogany. Understanding these nuances helps us at Jsylvl guide customers to the right birch product for their specific needs, whether it's for sturdy furniture made from birch or for intricate woodworking.

At our factory, we often utilize birch veneers from various species of birch depending on the desired properties of the engineered wood product, such as birch plywood or LVL. The choice of birch species can affect the strength, flexibility, and finish of the final product. For instance, a birch species with a finer grain might be preferred for applications where a smooth surface is critical. We also consider the birch wood’s response to adhesives and treatments. While all birch wood shares core similarities, acknowledging these different types of birch wood is crucial for optimal product development and application. This ensures that when a customer orders birch products, they receive material that meets their performance expectations.

Is Birch a Hardwood or Softwood? Unpacking Birch Wood’s Strength and Durability.

This is a fundamental question: Birch is a hardwood. Botanically, hardwoods come from deciduous trees (trees that lose their leaves annually), while softwoods come from coniferous trees (evergreens). Birch trees are deciduous, placing birch wood firmly in the hardwood category. This classification is important because hardwoods are generally denser and more durable than softwoods, making them suitable for applications requiring strength and longevity.

The durability of birch wood is one of its key selling points. While it's not the hardest of all hardwoods (ranking below species like oak or maple in Janka hardness), it is certainly sturdy and durable enough for a wide range of uses, including furniture, cabinetry, and high-quality plywood. For instance, Yellow Birch has a Janka hardness rating of around 1260 lbf, making it quite resistant to dents and wear. White Birch is a bit softer, around 910 lbf, but still offers good durability for many applications. This inherent strength makes birch a reliable material for projects that need to withstand daily use. We often highlight the durability of our birch-based products to customers who are looking for long-lasting solutions.

However, it's important to qualify the durability of birch wood. While strong, birch is susceptible to rot and insect attack, especially if exposed to moisture or outdoor conditions without proper treatment. This is a common characteristic of many hardwoods, not just birch. Therefore, for exterior applications or in humid environments, birch wood needs a protective finish or treatment. Indoors, however, its durability shines, making it a great choice for items that need to be both attractive and robust. This is a key consideration for buyers like Mark, who need to ensure the longevity of the components they procure. Our Structural Plywood often incorporates robust wood species suitable for demanding applications.

What Are the Shining Advantages of Using Birch Wood in Your Projects?

The advantages of using birch are numerous, making it a go-to material for many manufacturers and woodworkers. Firstly, birch wood is known for being relatively easy to work with. It machines well, meaning it’s easy to cut, shape, and drill with both hand and power tools. This workability reduces manufacturing time and effort, which is a significant benefit for B2B clients. Furthermore, birch wood glues effectively and can be nailed or screwed with good holding power, simplifying assembly processes.

Secondly, birch wood offers an excellent surface for finishing. It sands to a very smooth finish, providing a great base for paints, stains, and clear coats. While birch can sometimes take stain unevenly if not properly prepared (a pre-stain conditioner is often recommended), its natural light color is attractive on its own and also makes it an ideal canvas for a wide range of paint colors. This versatility in finishing is a major plus for furniture and cabinet makers who need to match various design aesthetics. The fine, uniform grain of birch contributes to this excellent finishing quality.

Thirdly, birch wood provides a fantastic balance of strength, aesthetics, and cost-effectiveness. It's generally more affordable than other hardwoods like oak, maple, or cherry, yet it offers comparable visual appeal and good structural integrity for many applications. This makes birch an economical yet high-quality option, especially for larger projects or when budget is a consideration. The fact that birch is widely available also contributes to its competitive pricing. For our customers, this means they can achieve a premium look and feel without an exorbitant price tag, which is always a win. The birch wood is a true workhorse in the industry.

Are There Any Potential Cons of Birch Wood to Keep in Mind?

While birch wood has many strengths, it's important to be aware of its potential downsides, or cons of birch wood. As mentioned earlier, one of the main concerns is that birch is susceptible to rot and decay and insect attack, particularly from pests like the bronze birch borer. This means birch wood is not inherently suited for outdoor use or in environments with high moisture unless it's thoroughly treated with preservatives or a very durable protective finish. Without such protection, birch can degrade relatively quickly when exposed to the elements.

Another consideration when using birch is its tendency to blotch when stained, especially with darker stains. The fine, dense grain of birch wood, while contributing to its smoothness, can absorb stain unevenly. This can result in a less-than-perfect finish if care is not taken during the staining process. Woodworkers often use a pre-stain wood conditioner or opt for gel stains to achieve a more uniform color. Alternatively, painting birch is a very popular option as it takes paint exceptionally well, offering a smooth, even surface. For some applications where natural wood grain is desired with a dark tone, other woods might be easier to finish.

Finally, while birch is a hardwood and quite sturdy, it’s not as hard or wear-resistant as some other hardwoods like red oak or hard maple. This means that for very high-traffic flooring or surfaces prone to heavy impact, birch wood might show dents and scratches more readily. This doesn't mean birch isn't durable enough for furniture or cabinetry – it certainly is – but for the most demanding applications, a harder species might be preferable. These are important factors for procurement officers like Mark, who need to balance cost with long-term performance and potential maintenance of birch products.

What Are the Most Common and Creative Uses of Birch Wood?

The uses of birch wood are incredibly diverse, a testament to its versatility and appealing characteristics. One of the most significant uses for birch wood is in the manufacturing of plywood. Birch plywood is highly regarded for its strength, stability, and smooth surface. It's used in everything from furniture construction and cabinetry to die-cutting, concrete forming (as film faced plywood), and even in the construction of musical instruments and skateboards. The consistent quality of birch veneers makes for superior birch plywood.

In furniture making, birch wood is a staple. It's strong enough for frames and load-bearing components, and its fine grain and light color make it attractive for visible parts. Birch is used to make chairs, tables, dressers, bed frames, and more. Its ability to take paint well has made it especially popular for children's furniture and modern designs that feature bold colors. Fine furniture can also be made from birch wood, often with a clear finish to highlight its natural beauty or stained to mimic more expensive woods like maple or even cherry. Birch was particularly prominent in Scandinavian-designed furniture during the mid-20th century, like in the 1960s and 1970s.

Beyond plywood and furniture, other common uses for birch wood include:

- Cabinetry: Both kitchen and bathroom cabinets benefit from birch wood's strength and smooth finish.

- Flooring: While not as hard as oak, birch is used for flooring, offering a lighter, contemporary look. It's often found in residential settings.

- Millwork and Trim: Baseboards, moldings, and door casings made of birch provide a clean, polished look.

- Toys and Craft Items: Being easy to work with and non-toxic (when unfinished or finished with safe coatings), birch is excellent to make toys, puzzles, and various craft items.

- Dowels and Spindles: The strength and straight grain of birch make it ideal for these turned parts.

- Firewood: While not its highest-value use, birch wood is also good firewood, known for burning hot and clean, especially its bark, which is an excellent fire starter.

- LVL (Laminated Veneer Lumber): Birch veneers are used in manufacturing high-strength LVL, like our F17 E14 LVL Structural timber, for structural applications.

The list of uses of birch wood goes on, showcasing why this hardwood remains a valuable resource.

How Does Birch Wood Lumber Compare to Other Woods like Oak or Maple?

When selecting birch wood lumber, it's helpful to compare it to other common hardwoods like oak and maple. In terms of hardness, birch (especially Yellow Birch) sits comfortably between the very hard (like hickory) and softer hardwoods. Maple, particularly Sugar Maple (Hard Maple), is generally harder than most birch species. Red Oak is also typically harder than Yellow Birch. This means maple and oak might offer slightly better wear resistance for applications like heavily used countertops or high-traffic floors.

Visually, birch wood offers a finer, more subdued grain pattern compared to the prominent, often coarser grain of oak. Oak has large pores and distinct growth rings, giving it a more traditional or rustic look. Birch, with its pale, creamy color and subtle grain, lends itself to more modern or Scandinavian aesthetics. Maple shares a similar light color and fine texture with birch, and they can sometimes be difficult to distinguish, though maple often has a more lustrous, almost shimmering quality. The choice often comes down to aesthetic preference and the desired finish.

Cost-wise, birch wood lumber is generally more affordable than maple and often comparable to or slightly less expensive than oak, depending on the grade and region. This makes birch a very attractive option for projects where budget is a key consideration without compromising too much on strength or appearance. In terms of workability, all three are good, but birch is sometimes considered a bit easier to machine than hard maple. Each wood has its strengths: oak for its classic look and toughness, maple for its extreme hardness and creamy appearance, and birch for its excellent balance of cost, workability, and clean aesthetic. We often see birch chosen for its ability to provide a high-end look at a more accessible price point.

A Woodworker's Compass: Tips for Working with Birch Wood

For the dedicated woodworker, birch wood can be a joy to work with, but a few tips can help achieve the best results. Firstly, because birch has a fine, tight grain, it’s essential to use sharp tools. Dull blades or bits can cause burning or tear-out, especially on end grain. Whether you're cutting, routing, or planing birch lumber, sharp tools will ensure clean, crisp edges and a smoother surface, reducing the amount of sanding needed later.

When it comes to sanding birch wood, patience is key to achieving that sought-after silky smooth finish. Start with a medium grit sandpaper (around 100-120) and progressively move to finer grits (up to 220 or even higher for a flawless surface before applying a finish). Be careful not to over-sand with coarse grits, as this can create dips or unevenness. Because birch is relatively hard, sanding can take a bit longer than with softer woods. Always sand with the grain to avoid visible scratches.

As mentioned, staining birch wood can be tricky due to its tendency to blotch. To combat this, always use a pre-stain wood conditioner. This helps to seal the wood pores more evenly, allowing the stain to penetrate uniformly. Alternatively, consider using gel stains, which sit more on the surface, or water-based dyes for a more controlled color application. If painting birch, a good quality primer is recommended to ensure excellent adhesion and a smooth, durable topcoat. Many woodworkers also appreciate that birch holds screws and nails well, but pre-drilling pilot holes, especially near edges, is always a good practice to prevent splitting, particularly with denser birch species. These woodworking nuances are what make birch both challenging and rewarding.

Is Birch Wood a Sustainable Choice? A Look at the Sustainability of Birch Wood.

The sustainability of birch wood is an increasingly important consideration for consumers and businesses alike. Generally, birch is considered a relatively sustainable wood choice. Birch trees are fast-growing and abundant in many parts of the Northern Hemisphere, including vast forests in North America, Europe, and Russia. This rapid growth cycle means that birch forests can regenerate more quickly than forests of slower-growing hardwoods.

Many birch forests are managed responsibly. When sourcing birch lumber or birch plywood, looking for certifications like those from the Forest Stewardship Council (FSC) can provide assurance that the birch wood comes from well-managed forests. FSC certification indicates that the harvest practices maintain the forest's biodiversity, productivity, and ecological processes. As a manufacturer, we at Jsylvl are committed to sourcing materials responsibly and can work with suppliers who provide certified birch when requested by customers like Mark, who are concerned about birch wood’s environmental impact.

However, like any natural resource, the sustainability of birch wood depends on proper forest management. Over-harvesting or illegal logging in any forest can lead to deforestation and habitat loss. Therefore, it's crucial to support a supply chain that prioritizes sustainable forestry. The birch ecosystem also plays a role, and responsible harvesting ensures these habitats are preserved. Overall, birch can be an environmentally friendly option, especially when compared to some tropical hardwoods or materials with a higher carbon footprint, provided it is sourced from a sustainable source. The widespread availability and fast growth of birch trees contribute positively to its sustainability profile, making birch a great choice for eco-conscious projects.

Our Commitment at Jsylvl: Ensuring Top-Quality Birch and Engineered Wood Products

At Jsylvl, my factory in China, we understand the importance of quality and consistency, especially when dealing with natural materials like birch wood. For customers such as Mark Thompson, who is a company owner and procurement officer, receiving reliable, high-grade products is paramount. Our identity as a factory specializing in engineered wood products means we handle birch not just as solid birch lumber, but also as a key component in products like birch plywood, Non-Structural Plywood, and Laminated Veneer Lumber (LVL).

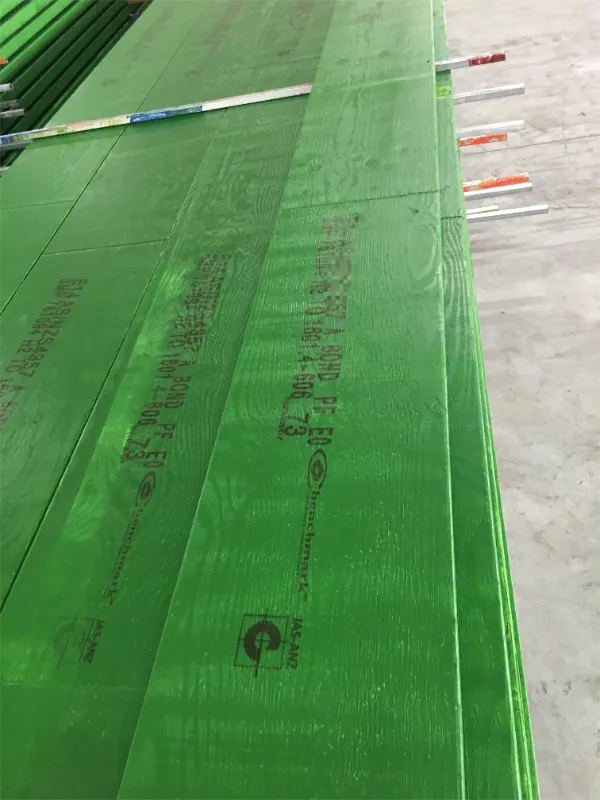

We implement rigorous quality control measures throughout our production lines. This starts with sourcing quality birch logs or veneers. We inspect for defects, ensure proper moisture content, and verify the grade of the birch wood. For engineered products like birch plywood, we pay close attention to the lamination quality, the type of glue used (e.g., E0 for low formaldehyde emissions), and the dimensional accuracy of the final panels. Mark's key concerns, such as quality inspection, certifications (like CARB compliance for exports to the USA), and consistent dimensions, are our daily focus. We aim to mitigate pain points like inconsistent quality or issues with moisture content by having stringent checks at each stage.

Our experience in exporting to demanding markets like the USA, North America, Europe, and Australia has taught us the value of transparency and reliability. We understand that delays in receiving shipments can severely impact construction schedules, so we work diligently on logistics. While birch is an excellent material, its properties must be consistent for it to perform as expected in furniture, cabinetry, or structural applications. By focusing on quality, we ensure that the birch wood and birch-based products leaving our factory meet the high standards our customers expect, making their purchasing decisions easier and their projects more successful. We aim to be more than just a supplier; we want to be a trusted partner in providing high-quality building materials, from birch specialties to other essentials like Oak flooring or robust OSB board.

Key Takeaways on Birch Wood:

To sum up our journey through the world of birch wood:

- What it is: Birch wood is a light-colored, fine-grained hardwood from birch trees, common in the Northern Hemisphere.

- Types: Main commercial types of birch wood include Yellow Birch (stronger) and White Birch (more workable), among others.

- Strength & Durability: Birch is a hardwood, offering good strength and durability for indoor applications, though it's susceptible to rot and decay outdoors without treatment.

- Advantages: It's easy to work with, takes paint and finishes well (with preparation for stain), and is cost-effective. Birch wood is a popular choice for furniture, cabinetry, and plywood.

- Disadvantages: Can blotch when stained, not as hard as oak or maple, and needs protection against insects and moisture for outdoor use. These are the main cons of birch wood.

- Common Uses: Widely used to make birch plywood, furniture, cabinetry, toys, millwork, and even firewood. The uses of birch wood are extensive.

- Comparisons: Birch wood lumber offers a finer grain than oak and is generally more affordable than maple.

- Woodworking: Requires sharp tools, careful sanding, and a pre-stain conditioner for best staining results. Birch is generally a woodworker-friendly material.

- Sustainability: Birch is often a sustainable choice due to fast-growing birch trees and responsible forest management practices. The sustainability of birch wood is a plus.

- Quality Sourcing: Partnering with a reliable supplier like Jsylvl ensures consistent quality, proper grading, and attention to detail for all your birch and engineered wood needs.

Birch wood truly is a remarkable material, offering a fantastic blend of aesthetics, performance, and value. We hope this guide has illuminated the many facets of birch and helps you in your future projects and sourcing decisions!

Post time: May-07-2025