As a procurement officer or construction company owner, you're constantly making decisions that impact project timelines, budgets, and the final quality of your work. Choosing the right materials is paramount. When it comes to concrete formwork and other demanding applications, one product consistently stands out: film faced plywood. But with so many suppliers and variations, how do you ensure you're getting a durable, reliable product? This guide is for you. We'll delve into what makes this type of plywood a powerhouse in the industry, explore its diverse applications, and give you the practical knowledge to make informed purchasing decisions, avoiding common pitfalls like inconsistent quality and project delays.

What Exactly Is Film Faced Plywood?

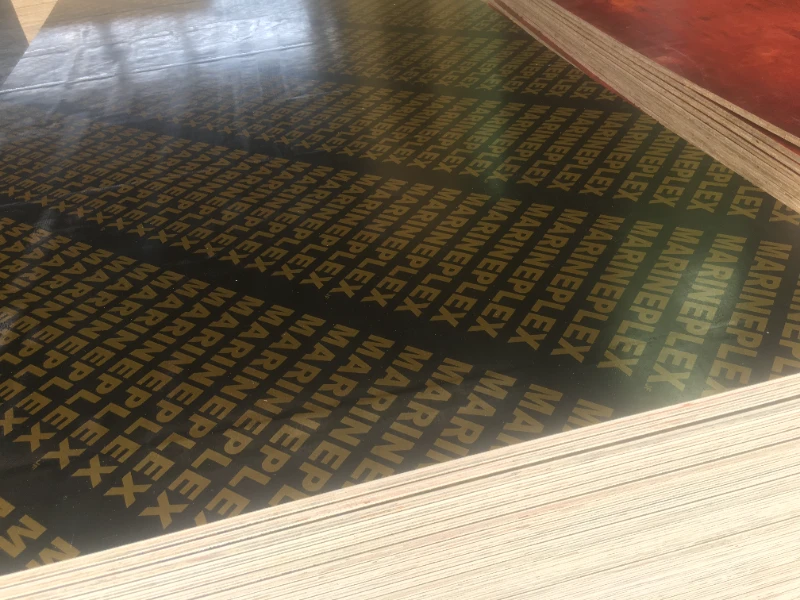

At its core, film faced plywood is a high-quality plywood panel with a special film coating on one or both sides. This isn't just any plywood; it's an engineered panel designed for superior strength and moisture resistance. The base panel is typically made from cross-laminated layers of thin wood veneer, bonded together under heat and pressure with a strong, waterproof adhesive. The real magic, however, lies in the surface.

The "film" is a paper sheet impregnated with a resin, most commonly a phenolic resin, which is then thermally fused to the surface of the plywood. This process creates a hard, smooth, and non-porous finish. The edges of the board are then sealed with waterproof paint, often an acrylic varnish, to prevent moisture from seeping into the core. This layered construction results in a panel that is incredibly robust, water-resistant, and ready for the rigors of construction sites. This special coating is what sets it apart and gives it its name.

How Is This Durable Plywood Made?

Understanding the manufacturing process can help you appreciate why quality control is so critical. As a plywood manufacturer, I can tell you that creating a top-tier panel is a multi-step, precision-driven operation. It all starts with selecting the right wood. High-grade logs, either hardwood or softwood, are peeled into thin sheets of veneer. These sheets are dried to a specific moisture content—a crucial step to prevent the finished board from warping later. Any defects in the veneer are removed to ensure a uniform core.

Next, these veneer sheets are coated with a powerful, waterproof adhesive, often a WBP (Weather and Boil Proof) glue, and laid up in alternating grain directions. This cross-graining technique is what gives plywood its exceptional dimensional stability and strength, resisting splitting and bending. The assembled layers are then moved to a hot press, where immense pressure and heat are applied. This permanently bonds the veneers together into a solid, monolithic panel. After pressing, the panels are trimmed to precise dimensions. The final, and most important, step for this type of plywood is the application of the phenolic film. The resin-impregnated paper is placed on the panel's surfaces and subjected to another round of heat and pressure, creating that smooth, durable finish that protects the wood core.

Why is the Phenolic Film Coating So Crucial for Durability?

The film coating is the single most important feature that defines film faced plywood and its performance. This isn't just a layer of paint; it's a high-density, resin-based barrier that fundamentally changes the panel's properties. The most common and effective type is the phenolic resin film. This thermosetting plastic creates a surface that is extremely hard, smooth, and resistant to both moisture and abrasion. Its primary job is to shield the wood core from direct contact with water, chemicals, and physical damage.

This protection is vital in applications like concrete formwork. When wet concrete is poured, it releases moisture and alkaline chemicals. The phenolic film prevents this moisture from being absorbed by the plywood, which would otherwise cause it to swell, warp, and degrade quickly. This ensures the panel maintains its shape and strength, allowing for multiple reuses. This exceptional durability and resistance to moisture are what make the panel so cost-effective over its lifespan. The smooth surface also provides a high-quality finish on the concrete, reducing the need for additional plastering or finishing work.

Hardwood vs. Softwood Core: What's the Best Choice for My Construction Projects?

When sourcing film faced plywood, you’ll encounter options with different core materials, primarily hardwood, poplar (a type of hardwood), birch, or softwood (like pine). The choice between them depends on your specific needs for strength, weight, and budget. For a procurement officer, understanding these differences is key to optimizing costs without sacrificing performance.

Hardwood cores, made from dense woods like eucalyptus or birch, offer the highest strength and durability. They are less prone to damage from impact and can withstand more reuses, making them ideal for heavy-duty construction and projects requiring a flawless concrete finish. A panel made from high-quality hardwood is the premium choice. In contrast, softwood cores are lighter and generally less expensive. While not as robust as hardwood, they are still a viable option for general-purpose formwork and applications where weight is a concern. Poplar core plywood strikes a good balance, offering good strength and a smooth finish at a more moderate price point.

Here is a simple comparison:

| Feature | Hardwood Core (e.g., Birch, Eucalyptus) | Softwood Core (e.g., Pine) | Poplar Core |

|---|---|---|---|

| Strength | Very High | Medium | Good |

| Durability | Excellent, more reuses | Good, fewer reuses | Very Good |

| Weight | Heavier | Lighter | Medium |

| Cost | Higher | Lower | Moderate |

| Best For | Heavy-duty formwork, high-rise buildings, architectural concrete | General construction, residential projects | Versatile use, good balance of cost and performance |

For most demanding construction projects, I always recommend a hardwood core. The initial investment is slightly higher, but the increased longevity and number of reuses deliver a better return over time.

What Are the Key Applications of Film Faced Plywood in Formwork?

The number one use for this material is, without a doubt, as formwork in construction. Its unique properties make it the perfect material for creating molds or a shutter system into which concrete is poured. The goal of formwork is to hold the liquid concrete in the desired shape until it cures and can support itself. Film faced plywood excels here for several reasons. Its high strength allows it to withstand the immense pressure of wet concrete without bulging or breaking.

The smooth, non-absorbent phenolic surface prevents the concrete from sticking to the formwork. This makes the "stripping" process—removing the shutter panels after the concrete has hardened—much easier and faster. It also leaves the finished concrete structures with a smooth, clean surface, which can significantly reduce post-finishing costs. Because the panel is so durable and waterproof, the same shuttering plywood can be reused many times, moving from one section of a project to the next, or from one job site to another. This reusability is a massive factor in its cost-effectiveness for construction companies. It is widely used in construction for walls, slabs, columns, beams, and girder molding boards.

Beyond the Construction Site: What Are Other Industrial Applications?

While its reputation is built on construction, the uses of film faced plywood extend far beyond concrete. Its combination of strength, a wear-resistant surface, and moisture resistance makes it a highly versatile material for various industrial applications. The same panel that creates a smooth concrete wall can be used to build a durable trailer bed.

One major area is the transportation industry. It's used in making the flooring and lining for trucks, trailers, vans, and shipping containers. The surface can handle the constant wear and tear of loading and unloading cargo, and some variants are available with an anti-slip pattern for added safety. Another significant application is in shipbuilding, where it's used for interior paneling, flooring, and furniture due to its excellent water resistance. Other common applications include manufacturing durable shelving systems, workbenches, stage platforms, playground equipment, and even agricultural buildings. Essentially, any application that requires a strong, smooth, easy-to-clean, and water-resistant panel is a candidate for film-faced plywood. It's truly a multi-purpose workhorse.

How Can I Spot High-Quality Phenolic Plywood?

This is a critical question for any buyer. As someone who has seen countless batches of plywood, I can tell you that not all panels are created equal. A bad batch can lead to on-site failures and project delays. Here’s a checklist I share with clients like Mark to help them assess quality, whether at a trade show or when receiving a shipment:

- Examine the Surface: The phenolic film should be smooth, glossy, and completely uniform. Look for any bubbles, dry spots, or areas where the film layer seems thin or improperly bonded. These are signs of a poor lamination process.

- Check the Edges: High-quality panels have perfectly sealed edges, usually with multiple layers of waterproof paint. Poorly sealed edges are the primary entry point for moisture, which can cause the layers to delaminate. The film layer and acrylic varnished edges are a sign of a quality product.

- Tap the Panel: Tap the surface of the board in different places. It should produce a solid, consistent sound. A hollow or dull sound can indicate voids or delamination within the core veneers. This simple test can reveal hidden defects.

- Verify the Thickness: Use calipers to measure the thickness at several points around the panel. Consistent thickness is a hallmark of good manufacturing and ensures a uniform fit in formwork systems. Inconsistency points to poor pressing or sanding. A product like 12mm Film faced plywood should be exactly that, with very little tolerance for error.

- Ask About the Glue: Inquire about the type of adhesive used. For applications involving moisture, always insist on WBP (Weather and Boil Proof) glue. A lower-grade glue, like MR (Moisture Resistant), will not hold up in demanding construction environments.

How Does Film-Faced Plywood Compare to Ordinary Plywood?

When considering materials, it's helpful to make a direct comparison. Compared to ordinary plywood, such as a non-structural or basic structural panel, film faced plywood offers a massive upgrade in performance, especially in specific applications. While both are made from wood veneer, the addition of the phenolic surface and edge sealing creates a far superior product for certain jobs.

Ordinary plywood, even if it uses waterproof glue, has a raw wood surface. This surface will absorb water, leading to swelling and degradation. It will also stick to concrete, making it difficult to strip and leaving a rough finish. It might last for one or two pours, but that's it. Film-faced plywood, on the other hand, is designed for this exact environment. Its smooth, non-porous surface ensures a clean release from concrete and can be used over and over again. While the initial cost is higher, its reusability and the superior finish it provides make it much more economical for concrete formwork in the long run. For applications requiring a durable, pre-finished, and water-resistant surface, there is no comparison. You can see a range of options, including basic non structural plywood 15mm, but for formwork, the specialized panel is king.

What Certifications Should I Look for When Sourcing from a Supplier?

This is where you separate the reliable suppliers from the risky ones. For a procurement officer importing from another country, certifications are your assurance of quality and compliance. They prove that a supplier has been audited by a third party and meets specific international standards. It's one of your best tools to combat the pain point of inconsistent quality and questionable claims.

Key certifications to look for include:

- ISO 9001: This demonstrates that the manufacturer has a robust quality management system in place, ensuring consistency from batch to batch.

- FSC (Forest Stewardship Council): This certification ensures that the wood used in the plywood comes from responsibly managed forests, an increasingly important factor for many projects in Europe and North America.

- Structural Ratings (e.g., F17, F14): For formwork applications in countries like Australia, specific structural ratings like Formply F17 1800×1200×17mm are required. These ratings guarantee the panel's strength and engineering properties.

- CARB P2 or EPA TSCA Title VI: These are American standards that regulate formaldehyde emissions from composite wood products. Compliance is mandatory for products sold in the USA and is a crucial indicator of safety and quality.

Always ask for copies of these certificates and don't hesitate to verify their authenticity with the issuing body. A trustworthy supplier will provide this information transparently.

What is the Expected Lifespan and Reusability?

The return on investment for film-faced plywood is a durable panel is directly tied to its reusability. The plywood’s service life depends on several factors: the quality of the panel itself (hardwood vs. softwood core, film quality), the care taken on the construction site, and the type of application. A high-quality hardwood panel can be reused anywhere from 10 to 50 times, or even more under ideal conditions.

To maximize the number of reuses and enhance longevity, proper handling is key. Panels should be cleaned after each use to remove concrete residue. Any scratches or holes in the film coating should be sealed to prevent moisture ingress. When stacking, small timber supports should be placed between panels to allow air circulation and prevent damage. By investing in a higher-quality panel and implementing good on-site practices, construction companies can dramatically lower their formwork material costs per project. This is the ultimate proof of the product's value.

Key Takeaways for Your Next Purchase

To summarize, here are the most important points to remember when sourcing film faced plywood for your business:

- The Film is Key: The phenolic film is what provides the crucial durability, smooth finish, and waterproof properties. This is its most important feature.

- Core Matters: For heavy-duty use and maximum reusability, choose a high-quality hardwood core. It offers the best long-term value.

- Inspect Before Accepting: Always perform a physical check. Examine the surface for defects, check the edge seals, tap for voids, and verify the dimensions.

- Ask for Certifications: Insist on seeing relevant certifications like ISO 9001, FSC, and any required structural or emissions ratings for your market.

- Think Long-Term: While the upfront cost may be higher than ordinary plywood, its reusability and the quality of the finish it produces make it a far more economical choice for formwork and other industrial applications.

Post time: Jun-25-2025