Oriented Strand Board, or OSB, is a super popular material in building stuff. You've probably seen it! But a big question many folks have is: "Is OSB waterproof?" It's a great question, especially if you're planning to use OSB for a project that might get a little wet. This article is here to clear things up. We'll dive into what OSB board really is, how well it handles water, and how you can make it even more waterproof. Understanding this will help you choose the right materials and make sure your projects last a long, long time, avoiding costly water damage. We'll also touch on how OSB compares to traditional plywood in terms of moisture resistance.

1. What Exactly is OSB and Why is it So Popular in Construction?

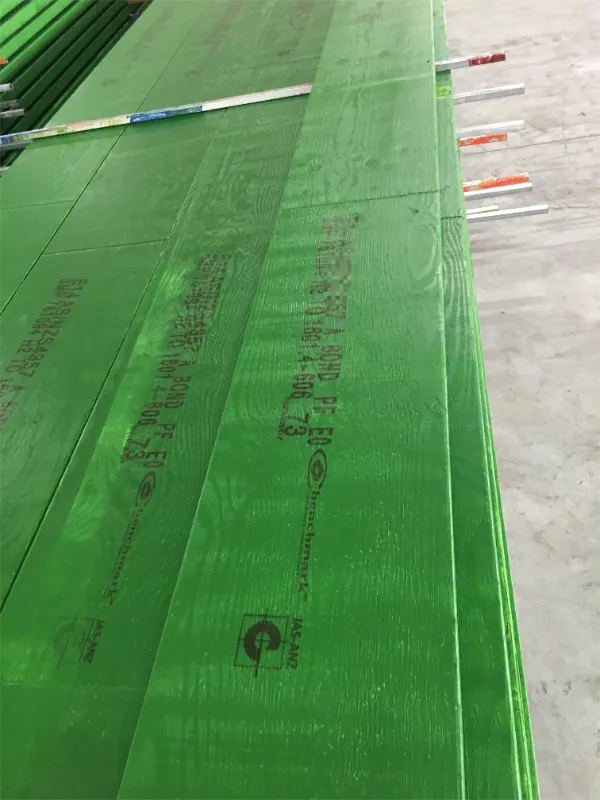

OSB, which stands for Oriented Strand Board, is a widely recognized engineered wood product. Think of it like a giant, super-strong sandwich made of wood! It's created by taking many small, rectangular wood strands or flakes, arranging them in specific cross-oriented layers, and then compressing them under high heat and pressure. What holds all these strand pieces together? A special moisture-resistant resin or adhesive. This layering technique is key; it gives OSB its impressive strength and stiffness, making it a reliable choice for many building applications.

You'll see OSB used in construction everywhere! It’s a common material for roof sheathing, wall sheathing, and as a subfloor underlayment. Why the popularity?

- Cost-effectiveness: Generally, OSB is more affordable than plywood, another common panel product. This helps keep construction budgets in check.

- Strength and Consistency: Because it's an engineer-designed product, OSB offers consistent quality and predictable performance. The layers of wood strands are specifically oriented to maximize strength.

- Large Panel Sizes: OSB is available in large, uniform sheets (like the common 4 x 8 osb board 15mm), which can make construction faster by covering large areas quickly. This makes it a favorite for both big construction projects and smaller DIY projects.

- Resource Efficiency: OSB can be made from smaller, faster-growing trees, which is often seen as a more sustainable use of timber resources compared to traditional plywood that might require larger logs.

While plywood is made from thin sheets of wood veneer glued together, OSB uses these smaller wood strands. This difference in manufacturing gives them slightly different properties, especially when it comes to exposure to moisture, which we'll explore next.

2. Is OSB Naturally Waterproof? Unpacking its Inherent Moisture Resistance.

This is the million-dollar question! The straightforward answer is: no, standard OSB is not completely waterproof. However, it's not like a paper towel that dissolves in water either. OSB does have a degree of moisture resistance built into it, thanks to the waxes and resin binders used during its manufacturing. These components help to slow down the rate of water absorption.

Think of it this way: if you spill a little water on an OSB panel and wipe it up quickly, it will likely be fine. The adhesive used in its construction is designed to withstand some incidental moisture. However, prolonged or repeated exposure to moisture is where problems can start. If OSB gets soaked and stays wet for a long time, the wood strands can absorb water, which can lead to swelling, especially at the edges. This is a key difference from materials that are inherently waterproof, like plastic or metal.

It's important to distinguish between "water-resistant" and "waterproof." OSB is generally considered water-resistant, meaning it can handle some moisture for a short period. But "waterproof" implies it can be submerged or constantly wet without any ill effects. Standard OSB doesn't quite meet that higher bar without some additional protection. The level of inherent moisture resistance can also vary depending on the grades of OSB, which we'll discuss next.

3. What are the Different Grades of OSB and How Do They Impact Water Resistance?

Not all OSB is created equal! There are different grades of OSB, and these grades tell you a lot about their strength and, crucially, their moisture resistance. Knowing these grades helps in choosing the right type of OSB for your specific project needs, especially if humid conditions or potential water exposure are concerns.

Here's a general breakdown of common OSB grades:

- OSB/1: This grade is designed for general-purpose use in dry conditions. It's typically used for things like interior fittings, packaging, and furniture where moisture isn't a major concern. It has the lowest moisture resistance among the grades.

- OSB/2: This is a load-bearing board also intended for use in dry conditions. You might find it used for interior structural applications like wall sheathing or subfloor in environments where humidity is consistently low. Its resistance to moisture is better than OSB/1 but still limited.

- OSB/3: This is where things get more interesting for moisture resistance. OSB3 is a load-bearing board specifically designed for use in humid conditions. It has a higher degree of moisture resistance due to the type and amount of resin used in its production. This makes OSB3 a popular choice for roof sheathing, wall construction, and flooring in many climates where occasional dampness is expected. It's often the go-to grade for many exterior-related applications, provided it receives adequate additional protection.

- OSB/4: This is a heavy-duty, load-bearing board designed for use in humid conditions and situations requiring even higher strength. It offers the best moisture resistance among the standard OSB grades. However, it's often more expensive and might be overkill for typical residential projects unless specific structural demands or very high moisture environments are present.

So, when you're considering OSB for a project, especially one that might face some dampness, looking for OSB3 is a good starting point. It offers a better baseline of water resistance compared to OSB/1 and OSB/2. Even with OSB3, for long-term outdoor use or areas with significant moisture, applying a waterproof coating or sealant is highly recommended.

4. Can OSB Be Used Outside Without Additional Protection?

This is a common question, especially for DIYers tackling outdoor projects. The short answer is: generally, no, standard OSB should not be used outside for extended periods without additional protection, even if it's a higher grade like OSB3. While OSB3 is designed for humid conditions and has enhanced moisture resistance, it's still a wood-based product. Continuous exposure to moisture, rain, snow, and fluctuating temperatures in outdoor conditions can eventually take a toll.

During construction, it's common for OSB sheathing on a roof or walls to be exposed to the elements for a short time before siding or roofing materials are installed. Most OSB, particularly OSB3, can handle this temporary exposure. However, leaving it unprotected indefinitely is asking for trouble. Without a protective layer, rainwater can seep into the OSB panel, especially at the cut edges, which are more vulnerable. This can lead to the wood strands absorbing water, causing the OSB to swell, warp, or even delaminate (where the layers start to separate). This compromises not only the appearance but also the structural integrity of the OSB.

For any OSB used outside, whether it's for sheds, playhouses, or even as part of larger construction projects like exterior sheathing or siding (if specifically designed for it), additional protection is crucial. This usually involves applying a good quality waterproof sealant, waterproof paints, or a weather-resistant barrier. This protective layer acts as a shield against air and water infiltration, helping your OSB last much longer and perform reliably.

5. What Really Happens to OSB When It Gets Wet?

Understanding what happens at a material level when OSB encounters excessive moisture is key to appreciating why additional protection is so important. OSB is made of wood strands, and wood is a hygroscopic material – meaning it naturally absorbs and releases moisture from its surroundings.

When an OSB board gets wet and stays wet:

- Swelling: The individual wood strands begin to absorb water. As they take on moisture, they expand in size. This is most noticeable in the thickness of the OSB panel. Edges are particularly vulnerable and can swell significantly if not properly sealed. This swelling can cause problems with fit and finish in a construction assembly.

- Warping and Buckling: If one side of an OSB panel absorbs more moisture than the other, or if the swelling is uneven, the board can warp, cup, or buckle. This distortion can affect the flatness of surfaces like floors or roofs and can stress connections to other structural members.

- Loss of Strength: While OSB is strong, prolonged saturation can weaken the bonds between the wood strands and the resin adhesive. The structural integrity of the OSB can be compromised, reducing its ability to carry loads. In severe cases, this can affect the safety of the structure.

- Delamination: In extreme situations of repeated wetting and drying or prolonged saturation, the layers within the OSB (though not layered like plywood, the oriented strand structure can still be affected) might start to separate. This is known as delamination and significantly weakens the OSB panel.

- Mold and Mildew Growth: Damp wood is an ideal breeding ground for mold and mildew. If OSB remains wet, these fungal growths can occur, leading to discoloration, musty odors, and potential health concerns. This is a common issue with any timber product experiencing prolonged water damage.

It's important to note that the extent of these issues depends on the duration of wetness, the grade of OSB, and whether any protective measures were in place. Minor, brief wetting that dries out quickly might have minimal impact, especially on OSB3. However, consistent exposure to moisture without adequate protection will almost certainly lead to some or all of the problems described above. This is why managing moisture content is critical when working with OSB.

6. How Can You Effectively Make Your OSB Waterproof for Outdoor Projects?

If you're planning to use OSB for outdoor projects or in areas prone to moisture, making it more waterproof (or, more accurately, highly water-resistant) is essential for longevity. Fortunately, there are several effective ways to provide this additional protection. The goal is to create a barrier that prevents water from penetrating the OSB board.

Here are the common strategies to protect your OSB:

- Waterproof Paints and Primers: Applying several coats of high-quality exterior-grade waterproof paints or primers can create a robust protective layer. Look for products specifically designed for wood or outdoor use. These paints not only add color but also form a film that repels water. Priming is especially important to ensure good adhesion of the topcoat.

- Sealants: Various types of sealant can be applied to seal the surface of the OSB.

- Liquid Rubber Sealants: These create a flexible, waterproof membrane over the OSB. They are excellent for applications needing high water resistance, like roofing details or areas with potential standing water.

- Polyurethane or Acrylic Sealants: These clear or colored sealant options can form a durable, water-resistant coating. They are often used for general sealing and can enhance the appearance of the OSB.

- Bitumen-Based Sealants: Often used for below-grade applications or roof sheathing, these provide excellent waterproof qualities but are typically black and may not be suitable where appearance is critical.

- Epoxy Resins: Applying a coat of epoxy resin can make OSB extremely water-resistant and also significantly increase its surface hardness and durability. This is a more intensive and often more expensive option but provides a very tough, waterproof finish.

- Varnish: For some applications where a more natural wood look is desired (though OSB isn't typically chosen for its aesthetic grain), an exterior varnish can provide a good level of moisture resistance. Multiple coats are usually needed.

- Weather-Resistant Barriers (House Wrap): While not making the OSB itself waterproof, for applications like wall sheathing, installing a house wrap over the OSB is standard practice. This material allows moisture vapor to escape from the wall cavity but prevents liquid water (like rain) from reaching the OSB.

Crucially, pay special attention to the edges! When you cut to size an OSB panel, the exposed edges are the most vulnerable points for water absorption. Always thoroughly seal the surface and especially the edges of any OSB pieces used in moist environments. No matter which method you choose, ensuring the OSB is clean and dry before application is vital for the coating or sealant to bond properly and provide effective moisture resistance. This step is fundamental to achieving a truly waterproof OSB assembly.

7. What are the Best Products to Use for Waterproofing OSB Board?

Choosing the right product to waterproof your OSB board depends heavily on the specific application, your budget, and the level of water resistance required. There isn't a single "best" product for all scenarios, but here are some excellent categories and considerations:

- High-Quality Acrylic Latex Exterior Paint: For many above-ground outdoor projects like sheds, playhouses, or siding (when OSB is used appropriately), a good quality acrylic latex exterior paint combined with a suitable primer is a great choice.

- Pros: Widely available, relatively easy to apply (brush, roller, or sprayer), comes in many colors, breathable (allows some moisture vapor to escape), and offers good moisture resistance.

- Cons: May require periodic reapplication, especially in harsh outdoor conditions. Multiple coats are essential.

- Tip: Look for paints labeled "waterproof" or "weather-resistant" and ensure you use a compatible primer designed for wood or engineered timber.

- Liquid Polyurethane or Elastomeric Sealants/Coatings: These products form a thick, durable, and often flexible waterproof membrane.

- Pros: Excellent water resistance, can bridge small cracks, good for roof sheathing under final roofing material, or areas needing a robust protective layer. Some are clear, preserving the OSB look if desired.

- Cons: Can be more expensive than paint, application might be more specific (follow manufacturer’s instructions carefully).

- Tip: Elastomeric coatings are particularly good as they can stretch and remain waterproof even if the OSB experiences minor movement.

- Epoxy Resin Sealers: Epoxy provides a very hard, durable, and highly waterproof coating.

- Pros: Creates an extremely tough and impervious surface, excellent for high-wear areas or where maximum water resistance is needed (e.g., some types of floor underlayment in wet areas, if compatible with final flooring).

- Cons: More expensive, can be trickier to apply (mixing two parts, limited working time), may yellow with UV exposure if not a UV-stable type or top-coated.

- Tip: Often used in marine applications on plywood, the principles apply to making OSB exceptionally water-resistant.

- Oil-Based Primers and Paints: Traditionally, oil-based products were favored for their penetration and water resistance on wood.

- Pros: Excellent adhesion, good water repellency.

- Cons: Longer drying times, strong odors, cleanup requires mineral spirits, and availability is decreasing due to VOC regulations in some areas.

- Asphalt or Bitumen-Based Coatings: These are heavy-duty waterproof coatings, often used for foundations or flat roofs.

- Pros: Very effective at blocking water.

- Cons: Typically black, can be messy to apply, not suitable for applications where appearance is important.

When making your choice, always read the product specifications carefully. Ensure it's suitable for engineered wood products like OSB and for the intended exposure (e.g., exterior, ground contact). Following the manufacturer’s application instructions is critical for achieving the desired waterproof osb result and reliable performance. For demanding structural applications, consulting with building professionals or considering products like Structural Plywood which may have different inherent characteristics, could be beneficial.

8. A Simple Step-by-Step Guide: How to Apply Waterproofing to an OSB Panel?

Applying a waterproof coating or sealant to an OSB panel isn't overly complicated, but doing it correctly is key to ensuring long-lasting protection against water damage. Here’s a general step-by-step guide. Remember to always consult the specific instructions provided by the manufacturer’s of your chosen waterproofing product, as application methods can vary.

Step 1: Prepare the OSB Surface

- Clean: The OSB board must be clean, dry, and free of dust, dirt, grease, or any loose debris. Use a stiff brush or a shop vacuum to clean the surface thoroughly. If there's any grease or oil, wipe it down with an appropriate cleaner and let it dry completely.

- Sand (Optional but Recommended): Lightly sanding the surface of the OSB with medium-grit sand-paper can help the primer and sealant or paint adhere better. It roughens the surface slightly, creating a better grip. Wipe away all sanding dust afterward.

- Inspect the OSB: Check for any damage, deep gouges, or loose splinters. Address these as needed before sealing.

- Ensure Dryness: The moisture content of the OSB should be low. Applying sealant to damp OSB can trap moisture, leading to problems later.

Step 2: Prime the OSB (Especially if Painting)

- If you're using waterproof paints, applying a good quality exterior wood primer is highly recommended. Primer helps the paint adhere better, provides a more uniform finish, and can offer additional moisture resistance.

- Apply the primer evenly with a brush, roller, or sprayer, following the manufacturer’s instructions for coverage and drying time.

- Special attention to the edges! Edges of an OSB panel are the most porous parts. Make sure to apply a generous coat of primer to all cut edges.

Step 3: Apply the Waterproofing Product

- Choose Your Weapon: Use a brush, roller (a thicker nap roller often works well for the textured surface of OSB), or an airless sprayer, depending on the product and the size of the area.

- First Coat: Apply a consistent, even coat of your chosen waterproof sealant, coating, or exterior paint. Don’t apply it too thickly, as this can lead to runs and improper drying. Work it into any surface texture.

- Focus on Edges Again: Ensure all edges receive thorough coverage. This is where water is most likely to try and seep in. It's often a good idea to apply an extra coat to the edges. Many professionals will "butter" the edges, working the sealant well into any small voids.

- Drying Time: Allow the first coat to dry completely according to the product's instructions. Drying times can vary based on temperature and humidity. Don't rush this step!

Step 4: Apply Subsequent Coats (If Needed)

- Most waterproof paints and many sealants require at least two coats for effective protection. Some products might recommend more.

- Apply the second (and any additional) coats in the same manner as the first, ensuring even coverage.

- Allow the final coat to cure fully as per the manufacturer's guidelines before exposing the OSB to harsh weather or putting it into service.

Step 5: Clean Up

- Clean your brushes, rollers, and any other equipment immediately after use, following the product’s instructions (e.g., soap and water for latex products, mineral spirits for oil-based).

By following these steps carefully, you can significantly enhance the water resistance of your OSB, helping it to withstand exposure to moisture and provide reliable performance in your DIY projects or construction projects. Remember, proper sealing is the best defense your OSB has against water damage.

9. Are There Special OSB Products Designed to Be More Water-Resistant from the Start?

Yes, absolutely! Recognizing the need for enhanced moisture resistance in many applications, manufacturers have developed specialized OSB products that offer better performance in humid conditions or where incidental exposure to moisture is likely. These products often go beyond the standard OSB3 grade.

Here's what to look for:

- Enhanced OSB / Water-Resistant OSB: Some manufacturers produce OSB panels marketed specifically as "water-resistant" or "moisture-resistant." These products often use advanced resin formulations and manufacturing processes to reduce water absorption and swelling. They might also include special waxes or other additives integrated throughout the OSB panel to improve its performance when wet. While still not completely waterproof to the point of indefinite submersion, they offer a significantly better defense against moisture than standard OSB. For example, products like osb board 18mm often come in grades like OSB/3 that are suitable for humid conditions.

- OSB with Integrated Weather-Resistant Barriers: Some innovative OSB products come with a factory-applied weather-resistant barrier or protective layer laminated directly onto one or both surfaces. This can save a step in the construction process (like installing separate house wrap) and provides immediate protection once the OSB is installed. This is particularly useful for roof sheathing and wall sheathing.

- Treated OSB: Similar to treated plywood or timber, some OSB products may undergo pressure treatment with preservatives that can enhance their resistance to moisture, rot, and fungal decay. However, this is less common than with solid lumber or plywood.

- OSB Subflooring with Enhanced Moisture Properties: For subfloor applications, especially in areas like bathrooms or kitchens where spills are more likely, some OSB subflooring products are engineered with extra moisture resistance. They often feature sealed edges and surfaces designed to prevent edge swell and provide a more stable base for the finished floor.

When selecting these specialized OSB products, it's important to:

- Read the Manufacturer’s Literature: Understand exactly what level of moisture resistance the product offers and its recommended applications.

- Check Certifications: Look for relevant certifications that verify its performance claims.

- Consider the Cost-Effectiveness: These enhanced OSB products might be more expensive than standard OSB. Evaluate if the added benefit justifies the cost for your specific project. For some applications, a standard OSB3 with a site-applied sealant might be sufficient.

Even when using these more moisture-resistant OSB types, it's still good practice to seal the surface of any cut edges made on site, as these expose the untreated core of the OSB panel. These advanced OSB options can provide an excellent starting point for building durable, moisture-resistant structures, particularly in challenging environments.

10. Keeping Your Waterproofed OSB Strong: Tips for Long-Lasting Protection and Maintenance.

Once you've gone through the effort to apply waterproof treatments to your OSB, a little regular maintenance can go a long way in ensuring it continues to provide reliable performance and protection against water damage. Even the best sealant or paint can wear down over time, especially in harsh outdoor conditions.

Here are some tips to protect your OSB long-term:

- Regular Inspections: At least once or twice a year, take a close look at your waterproofed OSB. Check for any signs of wear and tear on the coating, such as cracks, peeling, blistering, or areas where the sealant might be thinning. Pay special attention to edges, joints, and areas around fasteners, as these are common points for water infiltration.

- Clean Annually: Gently clean the surface of the waterproofed OSB to remove dirt, grime, mold, or mildew. A mild detergent and water solution is usually sufficient. Avoid harsh chemical cleaners or high-pressure washing that could damage the protective layer.

- Touch-Up Damaged Areas Promptly: If you find any small cracks or chips in the waterproof coating, touch them up as soon as possible with the original sealant or paint. This prevents minor issues from becoming bigger problems where water can seep in and compromise the OSB underneath.

- Reapply Sealant or Paint as Needed: Depending on the product used and the level of exposure, you may need to reapply a fresh coat of waterproof sealant or exterior paint every few years. The manufacturer’s guidelines for the product you used can often provide an estimate for its lifespan. If the coating looks faded or worn, it's probably time for a refresh.

- Ensure Proper Drainage: For any OSB used outside, ensure that water can drain away from it. Avoid situations where water can pool on or against the OSB. For example, ensure gutters are clean and directing water away from OSB siding or that there's good airflow around structures built with OSB.

- Check for Structural Issues: Periodically inspect the OSB itself for any signs of swelling, warp, or softness, which could indicate that moisture is getting through the protective barrier. If you find such issues, you'll need to address the source of the moisture and repair or replace the affected OSB and then re-seal it properly.

By being proactive with maintenance, you can significantly extend the life of your OSB installations and ensure their continued structural integrity and resistance to the elements. This little bit of special attention can save you from more costly repairs down the line and keep your construction projects or DIY projects looking good and performing well for years. For those building robust frameworks, considering highly engineered options like F17 E14 LVL Structural timber alongside well-protected OSB can create an even stronger and more durable structure. If you are looking for a high-quality finished floor to go over your well-prepared OSB subfloor, options like Oak flooring offer beauty and durability.

Key Takeaways on OSB and Waterproofing:

- What OSB Is: OSB (Oriented Strand Board) is an engineered wood product made from wood strands bonded with resin; it's strong and cost-effective for construction projects.

- Natural Resistance: Standard OSB is water-resistant, not fully waterproof. OSB3 is designed for humid conditions and offers better moisture resistance.

- Risks of Moisture: Prolonged exposure to moisture can cause OSB to swell, warp, lose strength, and develop mold.

- Waterproofing is Key: For outdoor use or wet environments, OSB needs additional protection with waterproof paints, sealants, or coatings.

- Edges are Vulnerable: Always seal the surface and especially the cut edges of OSB panels to prevent water absorption.

- Product Choice Matters: Select waterproofing products based on the specific application and follow manufacturer’s instructions.

- Maintenance is Important: Regularly inspect and maintain the waterproof coating to ensure long-lasting protection for your OSB.

- DIY-Friendly: Waterproofing OSB is a manageable task for many DIY projects and essential for home improvement.

Post time: May-30-2025