If you've ever worked with plywood, chances are you've encountered the frustrating phenomenon of warping. That once flat sheet of wood starts to cup, bow, or twist, throwing a wrench into your carefully laid project plans. As someone who has been in the wood panel products industry for years, supplying materials like LVL Timber and plywood worldwide from our factory in China, I, Allen, understand this topic well. Many of our customers, including experienced procurement officers like Mark Thompson from the USA, prioritize material stability. This article will delve into the common causes wood warping in plywood, explore how factors like plywood thickness and grade play a role, and offer practical advice to keep your plywood flat and your woodworking or construction projects on track. Understanding these factors will not only help you select better materials but also save you time and money in the long run.

What Exactly is Plywood Warping and Why is it a Common Woodworking Topic?

Plywood warp is any deviation from a perfectly flat plane. It can manifest in several ways:

- Cupping: The edges of the board are higher or lower than its center, forming a curve across the width.

- Bowing: The plywood sheet curves along its length, like a bow.

- Twisting: One or more corners are not on the same plane as the others.

- Kinking: A localized distortion often caused by a defect in a layer.

This issue is a hot topic in many a woodworking forum and among construction professionals because warped plywood can be a nightmare. Imagine trying to build a perfectly square cabinet with a cupped door, or lay a subfloor with bowed panels. The finished look is compromised, joints don't align, and structural integrity can be at risk. For DIY enthusiasts and professional builders alike, dealing with warp means lost time, wasted material, and increased costs. The explanation for why plywood might warp is often multifaceted, involving the inherent nature of wood and how the plywood is manufactured, handled, and used. Understanding these underlying causes wood is the first step to prevention.

At our factory, we often discuss these challenges with clients. When a builder receives a shipment, the last thing they want to see is a pile of unusable, warped plywood. This is why quality control, from the log to the final plywood sheet, is so critical. A slight warp might be manageable for some applications, but for others, even a minimal deviation can render the material useless. The visible signs of warp are usually obvious, but sometimes it's subtle until you try to fit the piece into your project.

How Does Moisture Content Cause Plywood to Warp?

The primary culprit behind most plywood warp is moisture. Wood is a hygroscopic material, meaning it naturally absorbs and releases moisture from and to the surrounding air. Think of it like a sponge. When plywood absorbs moisture – say, if it gets wet or is stored in a damp basement – its wood fibers expand. Conversely, when it loses moisture in a dry environment, the fibers contract. The problem arises when this absorption or release is uneven. If one side of a plywood sheet is exposed to more moisture (or dries out faster) than the other, that side will expand or contract more, causing wood to warp. This imbalance is a significant factor.

For instance, if you lay a plywood sheet on a concrete floor, the bottom side might absorb moisture from the concrete while the top side remains relatively dry, leading to cupping. Similarly, direct sunlight on one side can rapidly dry it, causing the plywood to warp away from the heat source. The internal balance of moisture within the plywood is crucial for maintaining its dimension and flatness. Fluctuations in humidity are a constant challenge, especially in regions with significant seasonal changes. As manufacturers, we pay close attention to the moisture content of the veneers before they are pressed into plywood, aiming for an equilibrium that suits most environments. However, post-manufacturing conditions are beyond our direct control, making proper handling by the end-user essential.

The rate at which wood gains or loses moisture also depends on the species of wood used in the plywood layers and the density of the material. Some wood species are more prone to movement than others. This is why understanding the environment where the plywood will be used and acclimatizing the material before installation can significantly help mitigate warp. We always advise our clients, especially those in the construction industry, to allow plywood to adjust to the ambient moisture levels of the job site for a few days before use. This simple step can prevent a lot of headaches down the line.

Can the Grade of Plywood Influence its Tendency to Warp?

Yes, the grade of plywood can certainly influence its susceptibility to warp. Plywood is graded based on the quality of the face and back veneers, typically using letters (A, B, C, D), where A is the highest quality with a smooth, paintable surface and few to no repairs, and D may have more imperfections like knots, knotholes, and splits. While the core veneers also play a role, the quality of the outer layers often dictates the grade. Lower grade plywood might use veneers that have more natural defects like larger knots or areas with irregular grain runs. These inconsistencies can create weak points or areas that respond differently to moisture changes, making the plywood more prone to warp.

For example, a knot is denser than the surrounding wood and will absorb and release moisture at a different rate. If a plywood sheet has many large knots on one side and fewer on the other, this imbalance can contribute to uneven movement and cause warping. Similarly, if there are voids or gaps within the inner plies (a void is essentially a hole in a layer), this can create an uneven structure that's less resistant to stress. Higher grade plywood, such as Baltic Birch plywood, often has more plies (layers) of thinner veneers with fewer defects, resulting in a more balanced and stable board. This careful construction helps to distribute stress more evenly, reducing the likelihood of warp.

When you select plywood, considering its intended use is important. For applications where a perfectly flat surface and minimal warp are critical, investing in a higher grade of plywood is often worthwhile. For instance, in furniture making or high-end cabinetry, the finished look demands stability. While no plywood is entirely immune to warp if mishandled, higher grade materials generally offer better resistance due to their superior construction and the quality of the wood veneers used. We often guide customers like Mark to select the appropriate grade based on their specific project requirements, balancing cost with performance.

Does Plywood Thickness Play a Role in Preventing Warp?

Plywood thickness is another significant factor when it comes to resisting warp. Generally speaking, thicker plywood is more rigid and therefore more resistant to warping than thinner plywood. A thicker sheet has more layers (plies) and a greater overall mass, which helps it to withstand the internal stresses caused by moisture fluctuations and temperature changes. Imagine trying to bend a thin piece of card versus a thick piece of cardboard – the thicker one offers much more resistance. The same principle applies to plywood.

For example, a 1/4 inch plywood sheet is much more flexible and prone to warp than a 3/4 inch plywood sheet. The increased number of cross-banded layers in thicker plywood contributes significantly to its dimensional stability. Each layer has its grain runs perpendicular to the adjacent ones, and this cross-graining is what gives plywood its strength and helps to counteract the natural tendency of wood to move. More layers mean more counteraction. However, it's important to note that even thick plywood can warp if subjected to extreme conditions or improper handling. No plywood won't warp at all if abused.

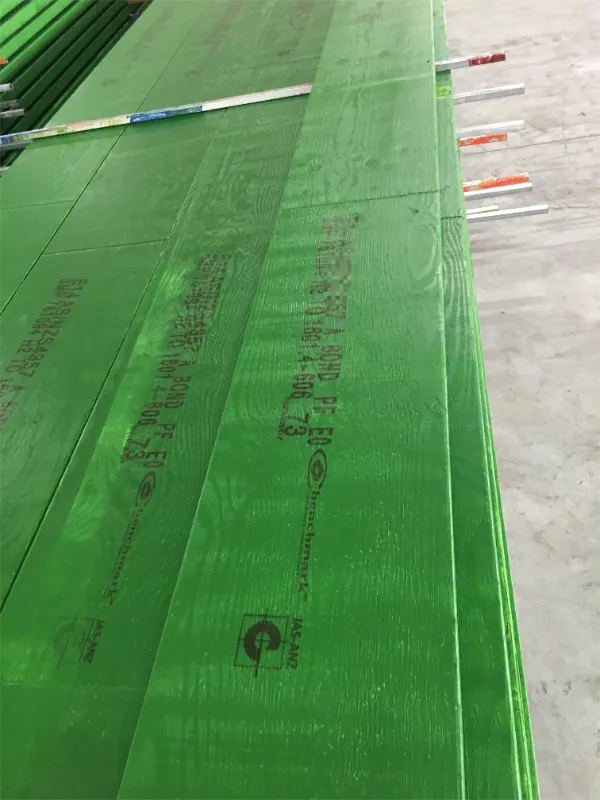

When planning a project, consider the structural demands and the need for flatness. If you're building something that requires high stability, such as tabletops, shelving, or subflooring, opting for a thicker plywood is a wise choice. While the initial cost might be higher, it can save you from the problems associated with warp. For certain applications, like concrete formwork, specific thicknesses and grades of film faced plywood for concrete formwork are used because they are designed to withstand significant stress and moisture exposure without excessive warp. Ultimately, the right plywood thickness provides a better balance between strength, stability, and cost for your next project.

Are Different Types of Plywood More Prone to Warping?

Yes, different types of plywood exhibit varying degrees of resistance to warp, largely due to their construction, the type of wood used, and the glue employed in their manufacture. For example, marine plywood is specifically engineered to be highly resistant to moisture and, consequently, to warp. It uses waterproof glue (typically WBP - Weather and Boil Proof) and is made from durable, high-quality veneers with minimal core gaps or voids. This makes marine plywood an excellent choice for applications where the wood will be exposed to high humidity or direct contact with wet conditions, such as boat building or exterior construction projects.

Standard interior plywood, on the other hand, might use less water-resistant glues and may have more permissible defects in its core layers, making it more susceptible to warp if it gets damp. Exterior plywood is a step up, using water-resistant glue, but it may not have the same quality of veneers or void-free core as marine grade plywood. Then there are specialty products like Baltic Birch plywood, which is known for its exceptional stability. It's made with more, thinner, uniform birch veneers, resulting in a very dense, flat, and strong sheet that resists warp well. This makes it a favorite for high-end cabinetry and furniture. Materials like MDF (Medium Density Fiberboard), while not technically plywood, are often used as an alternative due to their excellent dimensional stability, though they have different strength properties and reactions to direct moisture.

The choice of wood species also matters. Some wood species are naturally more stable than others. Plywood made from species that have a lower coefficient of expansion and contraction will generally be less prone to warp. As a manufacturer, we offer various types of plywood, including high-quality structural plywood, each suited for different applications. It's crucial to select the right type of plywood for your specific intended use to achieve the best results and minimal warp. Careful selection at the outset can prevent a lot of frustration later.

What are the Best Practices for Storing Plywood to Avoid Warping?

Proper storage is absolutely essential if you want to prevent your plywood from warping. Even the highest grade or thickest plywood sheet can warp if stored incorrectly. The key is to keep the plywood flat, dry, and in a stable environment. Ideally, plywood should be stored horizontally on a level surface. If you need to stack multiple sheets, ensure they are supported evenly across their entire surface. Using "stickers" or "bolsters" – small, evenly spaced pieces of lumber – between layers of plywood and between the bottom sheet and the floor can help. These create air channels, allowing for even air circulation around each sheet, which helps to equalize moisture content and prevent one side from absorbing more moisture than the other.

Avoid storing plywood directly on concrete floors, especially in a basement or garage, as concrete can transmit moisture. If you must store it in such locations, elevate the pile off the floor with a vapor barrier (like a plastic sheet) underneath the supports. The storage area should also be protected from direct rain, snow, and excessive sunlight. Rapid changes in temperature and humidity are the enemy of flat plywood. A climate-controlled environment is best, but if that's not possible, aim for a location that is relatively dry and has stable temperature conditions. Never store plywood leaning vertically against a wall for extended periods, as this will almost certainly cause warping due to uneven support and stress.

We often advise our clients, including large construction companies, on best practices for on-site storage. A little bit of planning and care in how you store your plywood can make a huge difference in its usability and the quality of your future projects. Think of it as protecting your investment. A well-stored plywood sheet is far more likely to remain flat and true, ready for cutting and assembly without the hassle of trying to straighten a warped board.

Table: Plywood Storage Do's and Don'ts

| Do | Don't |

|---|---|

| Store plywood flat on a level surface | Store plywood vertically for long periods |

| Use stickers for air circulation | Store directly on concrete floors |

| Keep plywood dry and covered | Expose plywood to rain or direct sun |

| Acclimatize plywood before use | Store in areas with high humidity swings |

| Support the entire sheet evenly | Stack unevenly or on an unlevel surface |

How Do Internal Stresses in Wood Contribute to Plywood Warping?

Beyond moisture, internal stresses within the wood itself can contribute to plywood warp. These stresses can originate from the way the tree grew or how the log was processed into veneers. Trees don't grow perfectly uniformly; factors like wind, slope, and competition for light can create tension wood or compression wood within the log. These areas have different densities and mechanical properties. When a log is peeled into thin veneers to make plywood, these internal stresses can be released unevenly, especially if the veneer layer is not properly conditioned or dried.

The annual growth ring structure of the wood also plays a part. As a tree grows, it adds a new ring of wood each year. The properties of this wood can vary. When these veneers are laid up and glued to form a plywood panel, if there's an imbalance in the stress characteristics of the different layers, it can predispose the plywood to warp over time, especially when triggered by changes in moisture or temperature. A good manufacturer will try to balance the panel by alternating the orientation of these stresses or by selecting veneers that are more uniform.

Even the process of drying lumber or veneers can induce stress if not done carefully. If wood is dried too quickly or unevenly, it can create case hardening, where the outer layers are dry and compressed while the inner core remains wet and in tension. When these veneers are used in plywood, these trapped stresses can later manifest as warp. This is one reason why the quality of the raw material (the log) and the precision of the manufacturing process are so critical in producing stable plywood. We invest heavily in understanding the characteristics of the wood species we use and optimizing our drying and pressing techniques to minimal these internal stress factors.

Can Manufacturing Quality Affect Plywood Stability and Warp?

Absolutely, the quality of the manufacturing process is a huge factor in determining how resistant plywood will be to warp. From the moment the log enters the mill to the final pressing of the plywood sheet, every step matters. The quality of the glue used is paramount. A good quality, waterproof or water-resistant glue will create strong, durable bonds between the veneer layers. If the glue spread is uneven, or if an inferior glue is used, the layers (plies) might delaminate or allow differential movement, leading to warp.

The construction of the plywood panel itself is also key. As mentioned, plywood gets its stability from cross-banded layers. It's crucial that each ply or layer is laid up correctly, with consistent thickness and no significant gaps or overlaps. The presence of a void (a gap or hole) within an inner ply can create a weak spot and an area of imbalance, making the plywood more prone to warp or even break under stress. High-quality manufacturers invest in machinery and quality control processes to minimize such defects. The pressure and temperature used during the pressing process must also be carefully controlled to ensure proper glue curing and bonding. Uneven pressure can lead to a plywood board that is not uniformly dense, which can contribute to warping.

At JSYLVL, we emphasize rigorous quality control throughout our multiple production lines. For specialized products like Laminated Veneer Lumber (LVL), which is an engineered wood product known for its strength and dimension stability, the manufacturing precision is even more critical. When customers like Mark are looking for reliable building materials, they are often concerned about the consistency from batch to batch. This consistency is a direct result of robust manufacturing standards. Choosing plywood from a reputable manufacturer that adheres to high-quality standards can significantly reduce the risk of dealing with warp.

What Steps Can Woodworkers Take During a Project to Minimize Plywood Warp?

Even if you've selected high-quality plywood and stored it properly, there are steps you can take during your woodworking or construction project to further minimize the risk of warp. One of the most important is acclimatization. Before cutting or installing plywood, let it sit in the environment where it will be used for several days. This allows the plywood to adjust to the ambient temperature and moisture levels, reducing the chance of it warping after installation as it tries to reach equilibrium.

When you apply finishes, try to balance the panel by finishing both sides equally, if possible. Sealing only one side of a plywood sheet can create an uneven exchange of moisture, leading to warp. If one side is sealed and the other isn't, the unsealed side will absorb or release moisture more readily, causing wood to cup towards the sealed side (if moisture is absorbed) or away from it (if moisture is lost). This is especially important for large, unsupported panels like cabinet doors or tabletops. Even if one side won't be visible, applying a coat of sealer can help balance the panel. Sealing the edge grain of plywood is also a good practice, as edge grain absorbs moisture much faster than the face grain. Some modern sealants even use an acrylic base to create a durable, moisture-resistant barrier.

During assembly, ensure that plywood components are well-supported and properly fastened. Avoid forcing warped pieces into place, as this can put stress on the entire project and may lead to problems later. If you encounter a slight warp in a piece of plywood, sometimes you can straighten it by applying moisture to the concave side and gentle pressure, but this is not always successful and depends on the severity of the warp. Careful planning of your cuts and assembly, along with these preventative measures, will contribute significantly to a successful project with minimal plywood warp. The goal is to maintain that flat, stable surface to achieve the desired finished look and ensure your hard work results in a durable, quality piece. Achieving that perfect polish on your final project starts with stable materials.

Where Can I Find Reliable Plywood That Won’t Warp for My Next Project?

Finding plywood that won’t warp (or, more realistically, has minimal tendency to warp) comes down to sourcing from reputable suppliers who prioritize quality. As a factory owner, I can tell you that not all plywood is created equal. The cheapest option might seem attractive initially, but if it leads to warped panels, project delays, and material wastage, it's no bargain. When looking for reliable plywood for your next project, consider suppliers who are transparent about their manufacturing processes, the grade of their plywood, and the types of wood and glue used. Look for certifications that indicate compliance with industry standards for quality and performance.

Many builders and DIY enthusiasts turn to specialized lumber yards or direct importers who have established relationships with quality-conscious mills. For our clients in the USA, Europe, and Australia, including those like Mark Thompson who purchase a range of engineered wood products, the ability to trust the supplier's quality control is paramount. This is especially true for materials like structural ply, where dimensional stability is critical for safety and performance. We also offer various non-structural plywood options for applications where appearance and flatness are still important, but the load-bearing requirements are different. For specific applications like subflooring or sheathing, OSB (Oriented Strand Board) can be a cost-effective and stable alternative to plywood.

Engaging with suppliers who understand the technical aspects of wood behavior and can provide guidance on the best material for your intended use is invaluable. Don't hesitate to ask questions about moisture content at the time of shipping, recommended handling procedures, and the specific characteristics of the plywood you are considering. While exhibitions are a great way to meet suppliers, diligent research online and asking for sample pieces for your own evaluation can also help in your careful selection process for future projects. Investing in good quality plywood from a trusted source is the best way to ensure your project starts on a flat, stable foundation.

Key Takeaways to Prevent Plywood Warp:

- Understand Moisture: Plywood warp is primarily caused by uneven moisture absorption or loss. Acclimatize your plywood!

- Grade Matters: Higher grade plywood generally has fewer defects and a more balanced construction, making it less prone to warp.

- Thickness for Stability: Thicker plywood is more rigid and offers better resistance to warping. Select appropriate plywood thickness for your project.

- Choose the Right Type: Different types of plywood (e.g., marine, exterior, Baltic Birch) offer varying levels of warp resistance. Match the plywood to the intended use.

- Store Properly: Always store plywood flat, in a dry, stable environment, with good air circulation.

- Manufacturing Quality: Source plywood from reputable manufacturers who use quality wood, glue, and maintain high construction standards.

- Balanced Finishing: When possible, apply finishes to both sides of the plywood sheet and seal the edges to control moisture exchange.

- Handle with Care: Proper cutting techniques and support during assembly will help maintain flatness.

Post time: May-23-2025